Benefits of Rigid-Flex PCB Design

Keywords: Rigid Flexible PCB Manufacturer, Rigid Flex PCB

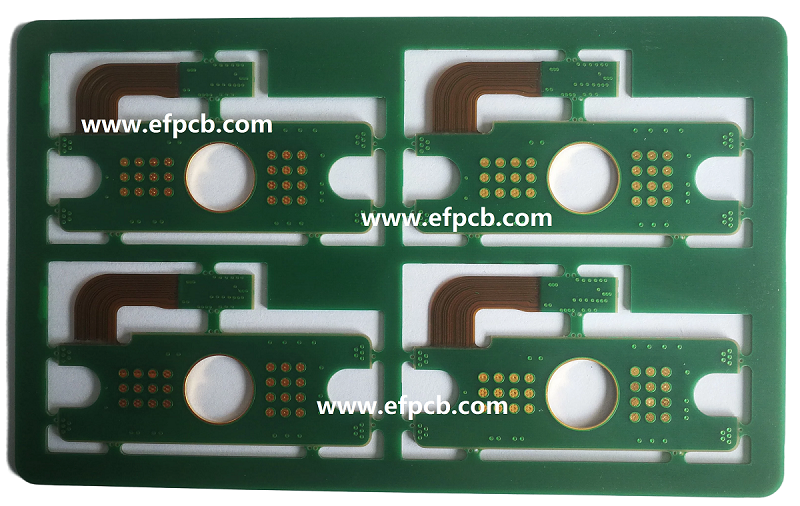

A Rigid Flex PCB is a hybrid circuit board that incorporates components from rigid and flexible circuit boards, creating a board that may be folded or continuously flexed. During the manufacturing process, the board is often formed into a flexed shape or curve. The flexible part of the board is often utilized for connections between rigid boards, enabling smaller, more space-efficient boards with narrower conductor lines. As connectors are typically unnecessary when flexible PCBs are used for connectivity, rigid-flex printed circuit boards become significantly lighter. Since these boards may be folded or twisted to create the proper shape for the product, rigid-flex PCB designs are a little more difficult to create. Greater spatial performance may be achieved by designing a board in three dimensions, which can then be applied in unique situations where weight and space reduction are required, such as in medical equipment.

Flexible circuit substrates and stiff circuit substrates are bonded together in a rigid-flex PCB. By using high-ductility electrodeposited or rolled annealed copper conductors that are photo-etched onto a flexible insulating film, rigid-flex PCBs go beyond the limitations of conventional rigid PCBs and make use of the special qualities of flex circuits.

Flexible polyimide materials, such as Kapton or Norton, and copper are bonded together in flex circuits under pressure, heat, and acrylic glue. You may install parts on both sides of the rigid board, just like with regular PCBs. A rigid-flex design does not utilize connectors or connecting wires between the parts because of the integration that takes place between stiff and flexible circuits. Instead, the system is electrically connected by the flex circuits.

The absence of connections and connecting cables in Rigid Flexible PCB Manufacturer achieves the following goals:

- increases the circuit's capacity for signal transmission without loss

- takes into account regulated impedance

- removes connection issues like chilly joints

- decreases weight

- makes room for more components

Compact design capabilities and minimal weight make rigid-flex boards a good choice for a variety of applications in the aerospace, medical, and consumer electronics industries.

Advantages of 360-degree bendable rigid-flex PCBs

- decreased space demand thanks to 3D capabilities

- Shock tolerance

- improved dependability

- Low in weight

- Higher connection reliability is ensured with fewer solder joints.

- PCB assembly procedures made simpler

Wide ranges of sophisticated design combinations are now possible because of improvements in rigid-flex circuit board materials, stack-ups, and structures. With these alternatives, there are tremendous opportunities to increase package density and design integration within a certain design of Rigid Flex PCB.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5PCB core raw material CCL

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact