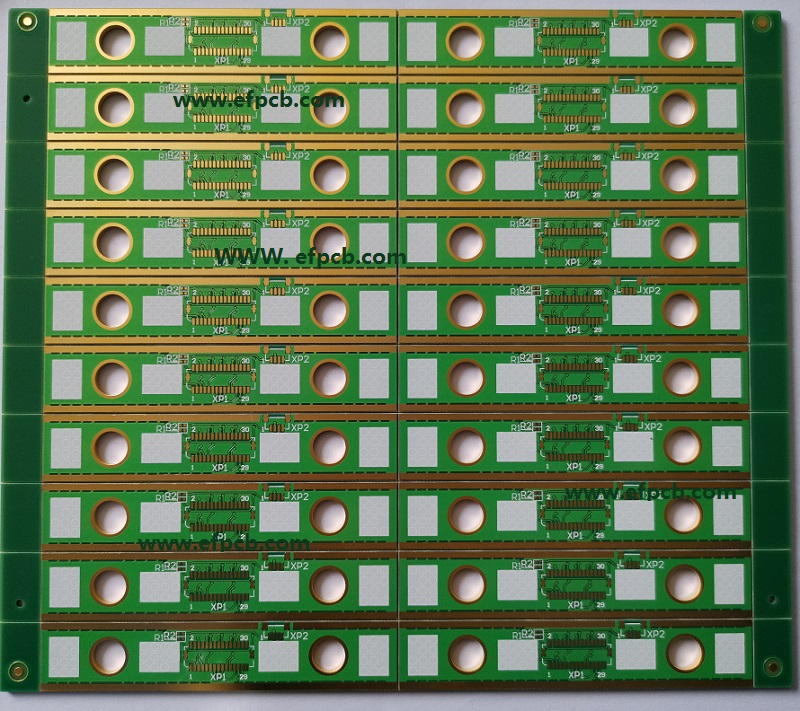

Facts Related to Plating Gold PCB

Keywords; Hard Gold PCB, Plating Gold PCB

In assembling a printed circuit board applying the surface completion is one of the last advances. After the patch cover process on a hard gold PCB the surface completion is regularly applied. It is essentially planned with the goal that it can forestall oxidation of the leftover uncovered copper. While most of the hardware is covered by the patch veil. This is essential on the grounds that oxidized copper can't be welded.

In exceptionally uncommon events, when a printed circuit board needs body gold, preceding the patch cover process this surface completion is applied to the copper. Gold completions are more costly in light of the fact that when the times comes for printed circuit load up gathering, the predictable completion merits the additional expense all the more particularly for plans that need a tight surface mount.

Delicate Gold

Delicate Gold is usually named as wire bondable gold. Contrasted with other gold completions it is gentler which for more grounded and more conductive associations permits it to effortlessly be reinforced more. The Gold never vanish at the reason behind patching or wire bond.

Its Utilization

Basically significant in light of the need to do gold wire holding.

Process used to apply the completion

The cycle is electrolytic that implies it utilizes a current to apply the completion (like Hard Gold, however doesn't have the hardeners and brighteners added). Before bind cover Plating Gold PCB is commonly applied.

Its basic estimations

Its virtue rate is 99.99%. Its ordinary thickness is 30 miniature crawls of Gold yet can surpass up to 100 miniature creeps in additions of 10.It is plated more than 100 - 200 miniature crawls of Nickel.

Hard Gold

Hard Gold is an electrolytic cycle and for toughness it has hardeners. Its plating is finished over a nickel finish. It very well may be alluded to as Profound Gold (the term Profound Gold is utilized to demonstrate that full boards are put in the plating tank).

Its Utilization

In light of its hardness, Hard Gold PCB can endure rehashed use and for gold fingers it is utilized most ordinarily.

Process expects to apply the completion?

It is an electrolytic cycle and it has hardeners added to it. While binding to Hard Gold an exceptionally dynamic transition ought to be utilized.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5Top HDI PCB Manufacturers (2024)

- 6PCB core raw material CCL

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact