HDI PCBs: Paving the Way for Advanced Electronics

In the domain of gadgets, advancement is persistent, pushing the limits of what's conceivable. High-Thickness Interconnect (HDI) Printed Circuit Boards (PCBs) stand at the very front of this upset, rethinking the scene of electronic plan and assembling. With their minimal size, upgraded execution, and complex capacities, HDI PCBs have turned into the foundation of present daily electronic gadgets. In this blog, we dig into the complexities of HDI PCB innovation, investigating its applications, benefits, and the extraordinary effect it has on different enterprises.

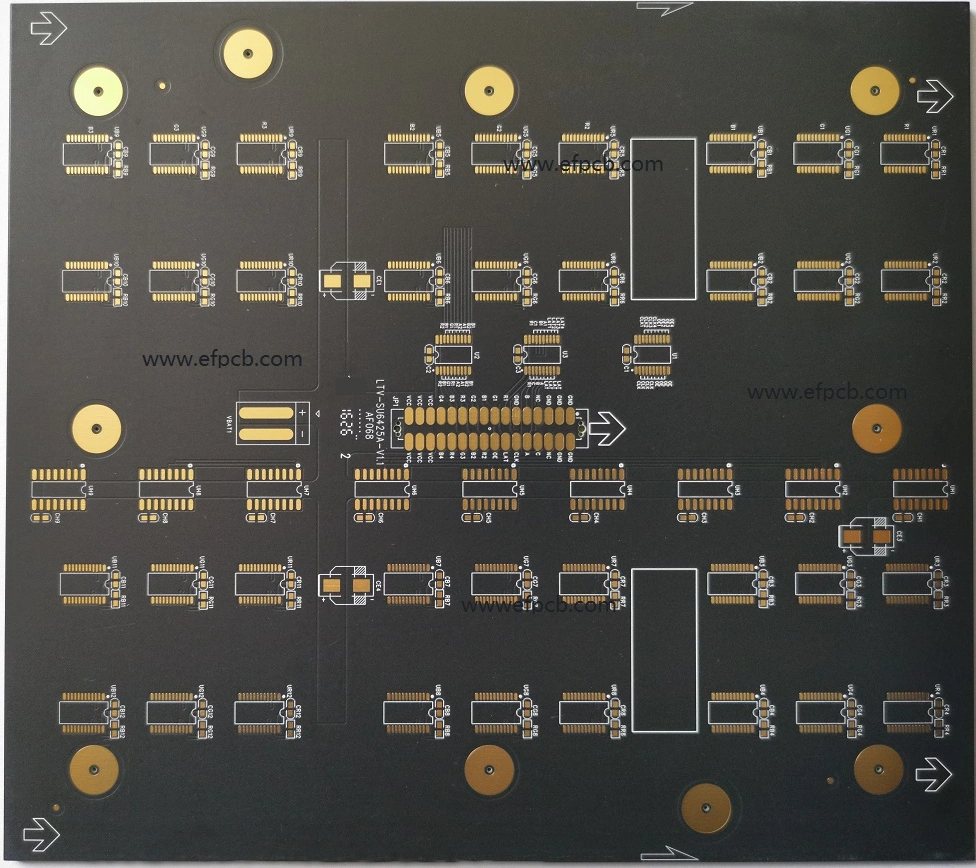

HDI PCBs

Customary PCBs have served commendably in endless electronic applications, yet as gadgets become more modest, lighter, and all the more impressive, the requirement for more modern hardware emerges. This is where HDI PCBs sparkle. Dissimilar to their customary partners, HDI PCBs use progressed producing methods to accomplish higher circuit densities, better lines, and closer dispersing between parts. By utilizing micro vias, blind vias, and covered vias, HDI PCBs expand the utilization of surface region, considering more noteworthy usefulness in a more modest impression.

Applications across Businesses

The flexibility of HDI PCB innovation reaches out across a bunch of enterprises, each profiting from its special capacities. In shopper hardware, for example, cell phones, tablets, and wearables, HDI PCBs empower makers to pack more elements into minimal plans without compromising execution. Auto hardware influence HDI PCBs to improve wellbeing, network, and productivity in vehicles. Clinical gadgets, aviation frameworks, and modern hardware likewise saddle the force of HDI PCBs to accomplish ideal execution in requesting conditions.

Advancements Driving HDI PCB Innovation

The development of HDI PCBs is filled by progressing headways in materials, cycles, and plan techniques. State of the art producing procedures, for example, laser penetrating, consecutive overlay, and controlled impedance, empower the production of progressively complex HDI structures with unrivaled accuracy and dependability. Novel substrate materials, including superior execution overlays and adaptable substrates, grow the skylines of HDI PCB applications, taking care of different industry prerequisites.

Difficulties and Contemplations

While HDI PCB innovation offers a plenty of advantages, its execution isn't without challenges. High-thickness plans require careful preparation and improvement to alleviate signal honesty issues, warm administration concerns, and assembling intricacies. Planners should find some kind of harmony between usefulness, manufacturability, and cost-viability to amplify the capability of HDI PCBs. Coordinated effort between creators, designers, and producers is fundamental to conquer these difficulties and convey inventive arrangements that fulfill the needs of current hardware.

High level Assembling Cycles

The complicated plan and development of HDI PCBs depend on an assortment of cut edge producing processes. Laser penetrating, for example, empowers the production of micro vias with distances across as little as 50 microns, working with thick interconnectivity between layers. Successive cover procedures take into consideration the joining of various layers with shifting thicknesses, streamlining space use and sign honesty. Controlled impedance steering guarantees steady electrical execution across fast sign ways, moderating sign debasement and contortion. These assembling progressions enable creators to push the limits of scaling down and execution, driving development across many businesses.

Materials Advancement

As well as assembling processes, materials development assumes a urgent part in progressing HDI PCB innovation. Elite execution substrate materials, like FR-4, polyimide, and fluid gem polymer (LCP), offer fluctuating levels of warm security, mechanical strength, and dielectric properties to suit different application necessities. Adaptable substrates empower the production of bendable and conformal PCB plans, ideal for applications with sporadic calculations or space limitations. Moreover, the coordination of cutting edge filler materials, conductive inks, and metal coatings upgrades the unwavering quality, toughness, and electrical execution of HDI PCBs in requesting conditions.

Plan Contemplations

Planning high-thickness PCBs requires cautious thought of different elements, including signal trustworthiness, power dissemination, warm administration, and manufacturability. Signal honesty examination devices, for example, electromagnetic recreation programming and impedance adding machines, help fashioners in improving follow calculations, through situations, and layer stack up to limit signal reflections, crosstalk, and timing mistakes. Power appropriation networks should be painstakingly intended to guarantee uniform voltage guideline and current conveyance across the PCB, particularly in fast advanced plans. Warm administration procedures, for example, heat sinks, warm vias, and copper pours, assist with scattering heat produced by dynamic parts and forestall warm out of control.

Growing further on the subject of HDI PCB innovation, how about we investigate a few explicit instances of its applications and the manners in which it is upsetting different enterprises:

Broadcast communications: The broadcast communications industry depends vigorously on HDI PCB innovation to help the consistently expanding interest for fast information transmission and organization network. In the sending of 5G organizations, for instance, HDI PCBs assume a basic part in supporting the complicated RF hardware and receiving wire frameworks expected for upgraded information rates and low idleness. Moreover, in the advancement of cutting edge media communications gear like base stations, switches, and switches, HDI PCBs empower smaller plans with further developed execution and unwavering quality.

Clinical Gadgets: In the clinical business, HDI PCB innovation is driving advancement in the improvement of cutting edge demonstrative and remedial gadgets. Scaled down clinical inserts, like pacemakers, defibrillators, and neurostimulators, benefit from the conservative size and high-thickness interconnectivity of HDI PCBs, considering exact position of parts and proficient utilization of restricted space inside the gadget. Besides, versatile clinical gadgets, including patient screens, imaging frameworks, and mark of-care demonstrative devices, influence HDI PCBs to convey constant information examination and correspondence capacities in a minimal and lightweight structure factor.

Auto Gadgets: The auto business is going through a huge change with the coming of electric vehicles (EVs), independent driving innovation, and associated vehicle frameworks. HDI PCBs are instrumental in driving these headways, empowering the improvement of minimal electronic control units (ECUs), sensor clusters, and correspondence modules that are fundamental for vehicle charge, independent route, and vehicle-to-everything (V2X) availability. By coordinating high level security highlights, shrewd infotainment frameworks, and prescient upkeep abilities, HDI PCBs add to the advancement of the auto environment towards more secure, more astute, and more feasible transportation arrangements.

Buyer Hardware: In the purchaser gadgets market, the interest for more modest, lighter, and more component rich gadgets keeps on driving the reception of HDI PCB innovation. Cell phones, tablets, smartwatches, and other versatile contraptions benefit from the reduced size and improved usefulness empowered by HDI PCBs, permitting producers to consolidate progressed elements like high-goal shows, multi-camera frameworks, and biometric sensors without settling for less on structure component or execution. Moreover, the multiplication of IoT gadgets, savvy home machines, and wearable devices depends on HDI PCBs to convey consistent network and clever usefulness in a minimized and energy-productive bundle.

Aviation and Guard: In the aviation and protection area where dependability, roughness, and execution are central, HDI PCB innovation assumes an essential part in strategic applications like flight, satellite frameworks, and military equipment. By utilizing progressed materials and assembling processes, HDI PCBs empower the advancement of lightweight and smaller gadgets with high unwavering quality and protection from brutal natural circumstances like temperature limits, shock, and vibration. Moreover, the scaling down and high-thickness interconnectivity managed by HDI PCBs support the mix of cutting edge highlights, for example, radar frameworks, correspondence organizations, and electronic fighting abilities, improving the functional viability and situational attention to military and aviation stages.

High-Thickness Interconnect Printed Circuit Sheets address a change in perspective in electronic plan and assembling, empowering phenomenal degrees of scaling down, execution, and usefulness. From customer gadgets to aviation frameworks, HDI PCB engages designers and trailblazers to push the limits of what's conceivable, introducing another time of network and accommodation.

HDI PCBs are specific circuit sheets intended to help more complicated and minimal electronic gadgets. Highlighting better lines, micro vias, and more tight part dividing, HDI PCBs empower higher circuit thickness and worked on electrical execution in a more modest impression. These sheets are fundamental for present day applications like cell phones, tablets, clinical gadgets, and auto hardware where space and unwavering quality are urgent. HDI innovation considers quicker information transmission, diminished power utilization, and upgraded usefulness, making it a basic part in the continuous development of state of the art gadgets, driving advancement across different cutting edge enterprises.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5Top HDI PCB Manufacturers (2024)

- 6PCB core raw material CCL

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact