HDI Printed Circuits: Enabling Compact, High Performance Electronics

In the complex scene of electronic parts and frameworks, HDI printed circuits (High-Thickness Interconnect) stand as crucial components in the progression of present day hardware. These complex circuit sheets have reformed the plan and usefulness of electronic gadgets, taking conceivable the jumps in innovation we frequently underestimate today. From cell phones to car gadgets, HDI innovation assumes a vital part in making gadgets more proficient, solid, and smaller. This investigation dives into the advancement, importance, and future direction of HDI printed circuits, revealing insight into their permanent effect on the gadgets business.

The Beginning and Development of HDI Printed Circuits

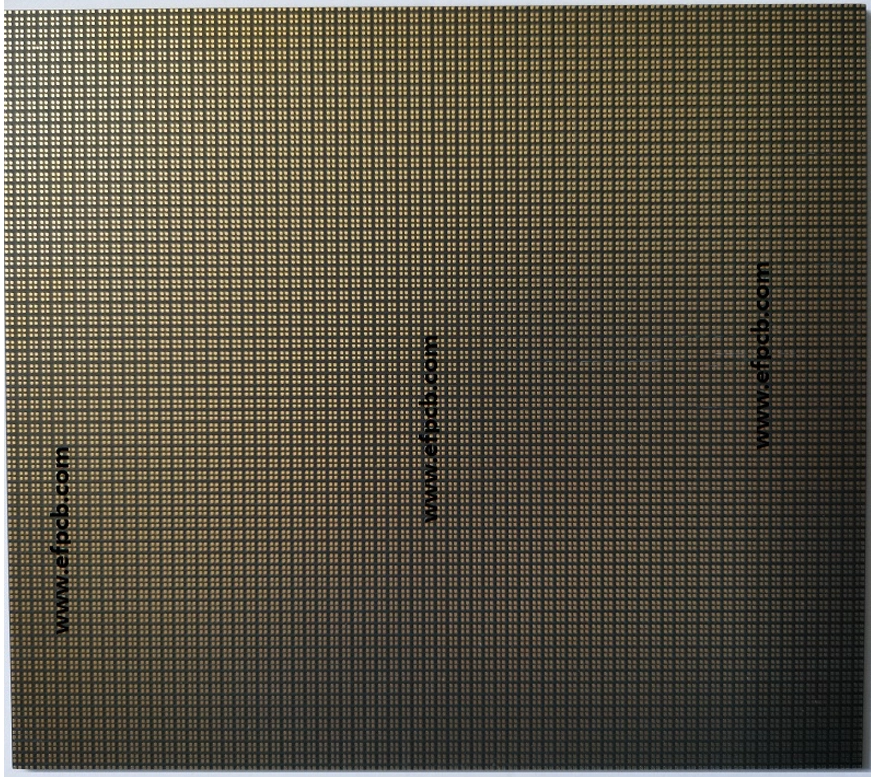

The excursion of printed circuit sheets (PCBs) started in the mid twentieth hundred years, yet the idea of HDI arose in the last part of the 1980s as the interest for additional smaller and proficient electronic gadgets developed. HDI innovation is described by its utilization of better lines, more modest vias (openings), and higher association cushion densities than conventional PCBs. This headway was not only a forward-moving step; it was a jump towards scaling down and practical thickness.

HDI printed circuits utilize progressed procedures, for example, microvias, developed layers, and the thick pressing of electronic parts. Microvias fundamentally diminish the board size by empowering layers to be stacked upon each other effectively. As hardware moved towards turning out to be more lightweight and thin, the job of HDI innovation turned out to be progressively huge. Today, it is beyond difficult to track down a superior execution electronic gadget that doesn't use HDI printed circuits in some limit.

The Meaning of HDI Printed Circuits in Current Gadgets

The essential charm of HDI printed circuits lies in their capacity to upgrade the presentation of electronic gadgets while at the same time lessening their size and weight. This is especially vital in businesses where space and productivity are fundamental, like in aviation, buyer gadgets, and clinical gadgets.

Improved Execution: HDI sheets support high-recurrence signals without loss of respectability, which is basic for the smooth activity of high velocity electronic gadgets. This has made them crucial in the domain of media communications and figuring.

Scaling down: The minimal idea of HDI innovation has been a key empowering influence in the improvement of more modest, more compact gadgets. Cell phones, wearable innovation, and minimal clinical gadgets owe a lot of their structure and capability to HDI printed circuits.

Further developed Unwavering quality: The high level assembling procedures related with HDI printed circuits bring about sheets that are more dependable and powerful, fit for enduring brutal conditions and delayed use. This makes them ideal for use in car and modern applications where solidness is pivotal.

Productivity and Manageability: HDI innovation adds to more prominent energy proficiency in electronic gadgets by decreasing electrical waste through superior circuit plan. Besides, the decrease in material utilization for HDI sheets lines up with the developing interest for more supportable assembling rehearses.

Difficulties and Arrangements in HDI Printed Circuit Creation

In spite of their benefits, HDI printed circuits present remarkable difficulties in creation. The intricacy of HDI board plan and the accuracy expected in assembling require progressed gear and talented ability. The cycle includes refined methods, for example, laser penetrating for microvias and consecutive cover, which can be cost-restrictive and in fact requesting.

Be that as it may, the gadgets business keeps on developing in conquering these difficulties. robotization, artificial intelligence driven plan enhancements, and headways in material science are assuming vital parts in making HDI innovation more available and savvy. Thus, the advantages of HDI printed circuits are opening up to a more extensive scope of utilizations and enterprises.

The Eventual fate of HDI Printed Circuits

The fate of HDI printed circuits is inherently connected to the patterns and requests of the gadgets business. As gadgets become more astute, more associated, and more incorporated into our day to day routines, the capacities of HDI innovation will keep on growing. Arising patterns like the Web of Things (IoT), wearable innovation, and adaptable hardware are pushing the limits of what is conceivable with HDI printed circuits.

Besides, the continuous scaling down pattern recommends that HDI innovation will assume an essential part in the improvement of cutting edge hardware. Developments in 3D printing and nano-innovation are supposed to open new roads for HDI printed circuits, empowering much more complicated and effective plans.

Manageability and HDI Printed Circuits

As the hardware business keeps on developing, so does its ecological impression. Here, HDI innovation offers a pathway to more economical gadgets through the decrease of materials utilized and the improvement of gadget effectiveness. Be that as it may, the test stays to further develop reusing techniques and the lifecycle the executives of HDI printed circuits. Developments in biodegradable substrates and recyclable conductive materials could additionally upgrade the manageability of HDI innovation, making it a foundation of eco-accommodating electronic gadget producing.

Arising Innovations and HDI Joining

Adaptable and Stretchable Hardware: Quite possibly of the most thrilling boondocks in gadgets is the advancement of adaptable and stretchable gadgets, which can be coordinated into clothing, worn on the skin, or utilized in conditions where customary unbending gadgets would fizzle. HDI printed circuits, with their minimized and powerful plan, are instrumental in this transformation. Advancements in adaptable substrates and conductive inks are making it conceivable to make HDI circuits that can twist, stretch, and flex, opening up new applications in wearable innovation, medical services checking, and, surprisingly, delicate mechanical technology.

Bio-incorporated Gadgets: The field of bio-coordinated hardware tries to foster gadgets that can consistently connect with organic frameworks. HDI innovation, with its capacity for high-thickness part joining and scaling down, is vital in making minimized, effective gadgets that can be embedded or worn on the body. These gadgets range from brain inserts for getting neurological problems bio-sensors for persistent wellbeing observing. The accuracy and unwavering quality of HDI printed circuits guarantee that these gadgets can work actually in the perplexing and touchy climate of the human body.

Quantum Registering: As we edge nearer to the acknowledgment of pragmatic quantum PCs, the interest for profoundly modern hardware that can work at very low temperatures and handle complex quantum communications increments. HDI printed circuits, particularly those made with cutting edge materials fit for leading at extremely low temperatures, are probably going to assume a basic part in the improvement of quantum figuring equipment. The capacity of HDI innovation to help thick, high velocity hardware makes it a possibility for interfacing and connecting quantum bits (qubits) with traditional registering frameworks.

Manageability and HDI Printed Circuits

As the gadgets business keeps on developing, so does its natural impression. Here, HDI innovation offers a pathway to more feasible gadgets through the decrease of materials utilized and the upgrade of gadget proficiency. Notwithstanding, the test stays to further develop reusing techniques and the lifecycle the executives of HDI printed circuits. Developments in biodegradable substrates and recyclable conductive materials could additionally upgrade the maintainability of HDI innovation, making it a foundation of eco-accommodating electronic gadget producing.

End

The effect of HDI printed circuits on current hardware couldn't possibly be more significant. By empowering more modest, more effective and more solid gadgets, HDI innovation has turned into a foundation of the hardware business. In spite of the difficulties related with their manufacture, progressing developments vow to keep HDI printed circuits at the bleeding edge of mechanical headway. As we plan ahead, obviously HDI innovation will keep on forming the advancement of electronic gadgets, making conceivable the inconceivable developments of tomorrow.

HDI printed circuits are progressed circuit sheets intended to help superior execution electronic gadgets in a reduced structure factor. By using barely recognizable difference follows, microvias, and more modest part dispersing, HDI PCBs empower higher circuit thickness and worked on electrical execution. These sheets are basic in businesses, for example, cell phones, wearables, car, and clinical gadgets where space is restricted however usefulness and unwavering quality are vital. HDI innovation considers quicker information transmission, diminished power utilization, and improved signal trustworthiness, making it a key empowering influence of state of the art electronic items and cutting edge developments across different areas.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5Top HDI PCB Manufacturers (2024)

- 6PCB core raw material CCL

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact