Is Underwriters Laboratory (UL) Certification Required for your PCB?

Keywords: Canada UL PCB

Whether it's our clothes logo, golf club's name, or the food brand, having that identification ensures that there will be no surprises. Because they have been recognized as something we trust, the clothing will fit, the golf ball will fly, and the meal will be good. We all realize that when it comes to consumer items, but we also want to instill the same degree of faith in the printed circuit boards that we are building for various purposes. This may be performed by sending our PCB designs to be tested and certified. Underwriters Laboratories is the most well-known testing agency (UL). You may reassure your consumers that the Canada UL PCB they are receiving is safe if it has UL certification. It has been approved as safe to use and was developed and built by particular standards and norms. Is this qualification, however, always required? Let us investigate more.

What Every Electronics Designer Should Know About PCB UL Certification

An engineer's thinking is continuously preoccupied with safety. Even with all of the models in the world, you still ask how your PCB would function in its physical form under a range of temperatures, ambient situations, and handlings. This could only be confirmed by extensive testing. If you intend to develop PCBs for appliance usage, audio, video, information technology, or medical usage, you must meet the highest safety requirements. This includes dealing with the specifics of UL certification. In this article, we'll look at what UL certification is, what type of requirements it needs for PCB designs, and how it affects your career as an electronics designer.

Why Should You Have Your Design Tested and Certified?

Certification indicates that your PCB has been tested and validated to satisfy specified safety criteria. While this is not a warranty or assurance of performance, it does give your consumers’ confidence that the board they get from you meets or exceeds industry requirements for the protection of electrical shock. Many end products now demand that PCBs meet these specifications. Industrial control equipment, video, and audio equipment, and Medical equipment, to mention a few industries, have these types of needs.

If you are making PCBs for an industry that does not have this criterion, your board may not need to be certified. This is also a promotional choice, since becoming board-approved may make your company more appealing than what your competitors have to offer. In any event, formally validating that your board was created by industry safety standards may provide you with some legal protection over not having such certification.

What exactly is Underwriters Laboratories (UL) certification?

Underwriters Laboratory is a well-known corporation that provides product safety certifications. This is a global safety certification and consulting firm founded in 1894. In a variety of sectors, they test items, document standards, and certify producers. Having a UL emblem on your board confirms that your Canada UL PCB was created by UL quality and safety requirements.

What Does the UL Mark on a PCB Mean?

When your PCB is UL Marked by your manufacturer, it means that it fulfills all specified safety and flammability regulations. A UL Mark specifically indicates:

- The base material in your PCB fulfills a flammability standard set by UL94. When exposed to a naked flame and then withdrawn, FR4 self-extinguishes in 10 seconds and does not leak any blazing particles. This testing scenario will be performed on each base material offered by a manufacturer.

- Your PCB's base material has the requisite level of resistance to ignite from exterior electrical sources.

- Your PCB's base material has the requisite electrical breakdown value. This is the voltage differential at which a base material's insulating qualities may begin to deteriorate and pose safety hazards.

- The core material in your PCB satisfies the UL 796A performance criteria for direct aid of current carrying capacity.

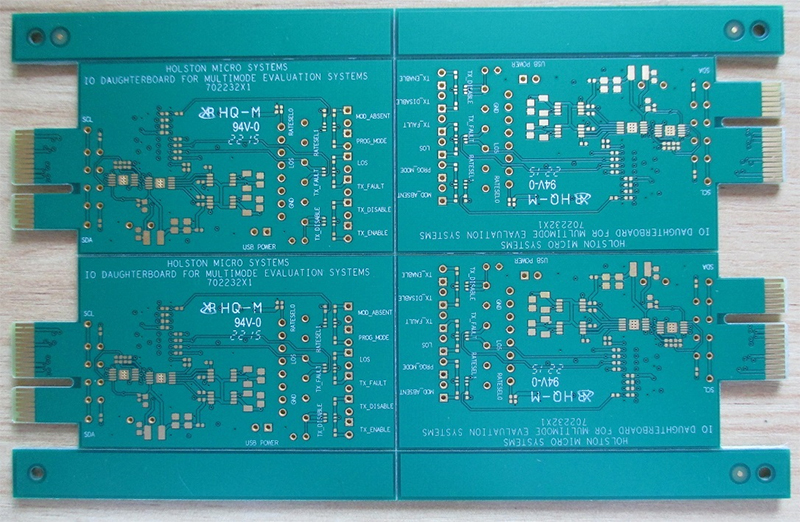

- The UL Mark will be printed on your silkscreen layer after your PCB has received it. In this case, UL94V-0 indicates that the board satisfies the UL94 flammability standards at flame class V-0. The E505603 is a one-of-a-kind UL Mark identification for a typical manufacturer, and the ML indicates that this is a Multi-Layer PCB.

Getting Your PCB Certification

The specifications for your PCB accreditation will be decided by the board's applicability in the end product for which it was built. As previously stated, particular sectors, like medical equipment, have specific criteria that must be satisfied and verified before your board can be utilized. The parameters are as follows:

- Specific flame resistance

- Compliance with maximum operating temperature (MOT) and direct support requirements (DSR)

- The lowest possible comparative tracking index (CTI) rating

If you are unfamiliar with this material or are having difficulty determining the application of particular standards, assistance is available. The technical expertise at Underwriters Laboratory can assist you in determining what characteristics you need to design for your PCB.

Your contract manufacturer can also be of service (CM). They can assist you in determining which factors require certification. They may also assist you in setting up your boards and sending them off for testing and certification.

Obtaining Your UL Certification

The good news is that obtaining a UL Marking for a PCB is a pretty simple process. As part of a UL compliance program, your manufacturer is responsible for the majority of UL regulations. Your manufacturer gets audited for UL compliance four times per year under this program. Random manufacturing boards will also be subjected to yearly testing for manufacturers generating Full Recognition PCBs.

When requesting a price for Canada UL PCB manufacturing, most supplier websites will have an area where you may specify your requirements for UL Marking.

Keywords: Canada UL PCB

Whether it's our clothes logo, golf club's name, or the food brand, having that identification ensures that there will be no surprises. Because they have been recognized as something we trust, the clothing will fit, the golf ball will fly, and the meal will be good. We all realize that when it comes to consumer items, but we also want to instill the same degree of faith in the printed circuit boards that we are building for various purposes. This may be performed by sending our PCB designs to be tested and certified. Underwriters Laboratories is the most well-known testing agency (UL). You may reassure your consumers that the Canada UL PCB they are receiving is safe if it has UL certification. It has been approved as safe to use and was developed and built by particular standards and norms. Is this qualification, however, always required? Let us investigate more.

What Every Electronics Designer Should Know About PCB UL Certification

An engineer's thinking is continuously preoccupied with safety. Even with all of the models in the world, you still ask how your PCB would function in its physical form under a range of temperatures, ambient situations, and handlings. This could only be confirmed by extensive testing. If you intend to develop PCBs for appliance usage, audio, video, information technology, or medical usage, you must meet the highest safety requirements. This includes dealing with the specifics of UL certification. In this article, we'll look at what UL certification is, what type of requirements it needs for PCB designs, and how it affects your career as an electronics designer.

Why Should You Have Your Design Tested and Certified?

Certification indicates that your PCB has been tested and validated to satisfy specified safety criteria. While this is not a warranty or assurance of performance, it does give your consumers’ confidence that the board they get from you meets or exceeds industry requirements for the protection of electrical shock. Many end products now demand that PCBs meet these specifications. Industrial control equipment, video, and audio equipment, and Medical equipment, to mention a few industries, have these types of needs.

If you are making PCBs for an industry that does not have this criterion, your board may not need to be certified. This is also a promotional choice, since becoming board-approved may make your company more appealing than what your competitors have to offer. In any event, formally validating that your board was created by industry safety standards may provide you with some legal protection over not having such certification.

What exactly is Underwriters Laboratories (UL) certification?

Underwriters Laboratory is a well-known corporation that provides product safety certifications. This is a global safety certification and consulting firm founded in 1894. In a variety of sectors, they test items, document standards, and certify producers. Having a UL emblem on your board confirms that your Canada UL PCB was created by UL quality and safety requirements.

What Does the UL Mark on a PCB Mean?

When your PCB is UL Marked by your manufacturer, it means that it fulfills all specified safety and flammability regulations. A UL Mark specifically indicates:

- The base material in your PCB fulfills a flammability standard set by UL94. When exposed to a naked flame and then withdrawn, FR4 self-extinguishes in 10 seconds and does not leak any blazing particles. This testing scenario will be performed on each base material offered by a manufacturer.

- Your PCB's base material has the requisite level of resistance to ignite from exterior electrical sources.

- Your PCB's base material has the requisite electrical breakdown value. This is the voltage differential at which a base material's insulating qualities may begin to deteriorate and pose safety hazards.

- The core material in your PCB satisfies the UL 796A performance criteria for direct aid of current carrying capacity.

- The UL Mark will be printed on your silkscreen layer after your PCB has received it. In this case, UL94V-0 indicates that the board satisfies the UL94 flammability standards at flame class V-0. The E505603 is a one-of-a-kind UL Mark identification for a typical manufacturer, and the ML indicates that this is a Multi-Layer PCB.

Getting Your PCB Certification

The specifications for your PCB accreditation will be decided by the board's applicability in the end product for which it was built. As previously stated, particular sectors, like medical equipment, have specific criteria that must be satisfied and verified before your board can be utilized. The parameters are as follows:

- Specific flame resistance

- Compliance with maximum operating temperature (MOT) and direct support requirements (DSR)

- The lowest possible comparative tracking index (CTI) rating

If you are unfamiliar with this material or are having difficulty determining the application of particular standards, assistance is available. The technical expertise at Underwriters Laboratory can assist you in determining what characteristics you need to design for your PCB.

Your contract manufacturer can also be of service (CM). They can assist you in determining which factors require certification. They may also assist you in setting up your boards and sending them off for testing and certification.

Obtaining Your UL Certification

The good news is that obtaining a UL Marking for a PCB is a pretty simple process. As part of a UL compliance program, your manufacturer is responsible for the majority of UL regulations. Your manufacturer gets audited for UL compliance four times per year under this program. Random manufacturing boards will also be subjected to yearly testing for manufacturers generating Full Recognition PCBs.

When requesting a price for Canada UL PCB manufacturing, most supplier websites will have an area where you may specify your requirements for UL Marking.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5PCB core raw material CCL

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact