Rigid-Flexible PCB Manufacturers Play a Crucial Role in Revolutionizing Electronics

Keywords: Rigid Flexible PCB Manufacturer

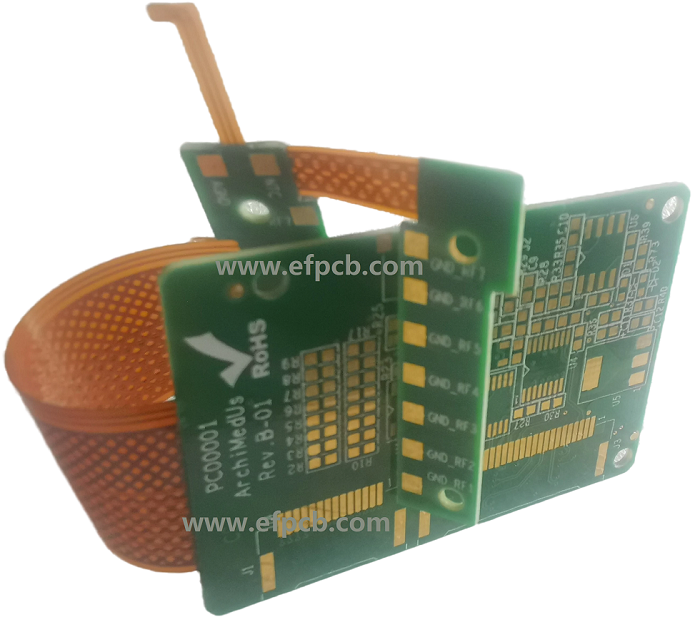

Rigid-Flexible PCBs from Rigid Flexible PCB Manufacturer are a hybrid of traditional rigid boards and flexible circuits. They offer the best of both worlds, combining the stability and reliability of rigid boards with the flexibility and space-saving advantages of flexible circuits. This unique combination allows designers to create three-dimensional electronic assemblies, making them ideal for applications where space is a premium.

The Role of Rigid-Flexible PCB Manufacturers:

Innovation in Design

A Rigid Flexible PCB Manufacturer is at the forefront of pushing the boundaries of electronic design. They work closely with engineers and designers to develop custom solutions that meet the specific requirements of a wide range of applications, from medical devices and aerospace technology to consumer electronics.

Material Expertise

Manufacturing Rigid-Flexible PCBs requires a deep understanding of materials that can withstand both rigid and flexible conditions. Manufacturers invest in research and development to identify and utilize materials that offer high reliability and durability in various environments. This includes selecting appropriate substrate materials and conducting thorough testing to ensure the final product meets stringent quality standards.

Precision Manufacturing

The production of Rigid-Flexible PCBs demands a high level of precision. Manufacturers leverage advanced manufacturing processes, such as laser cutting and etching, to create intricate patterns on both rigid and flexible sections. This precision is crucial for ensuring the electrical integrity of the circuit and the mechanical reliability of the flexible portions.

Customization for Specific Applications

Rigid-Flexible PCB manufacturers recognize the diverse needs of different industries. They provide customization options that allow designers to tailor the boards to the unique requirements of their applications. Whether it's a wearable device that needs to bend with the body or a space-constrained medical implant, Rigid-Flexible PCBs can be adapted to suit a myriad of use cases.

Quality Assurance

Ensuring the reliability of electronic components is paramount. Rigid Flexible PCB Manufacturer implements rigorous quality control measures throughout the manufacturing process. This includes thorough testing of the finished boards to identify and rectify any defects, ensuring that the final product meets or exceeds industry standards.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5Top HDI PCB Manufacturers (2024)

- 6PCB core raw material CCL

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact