Role of Radio Frequency Printed Circuit Boards

Keywords: Radio Frequency PCB

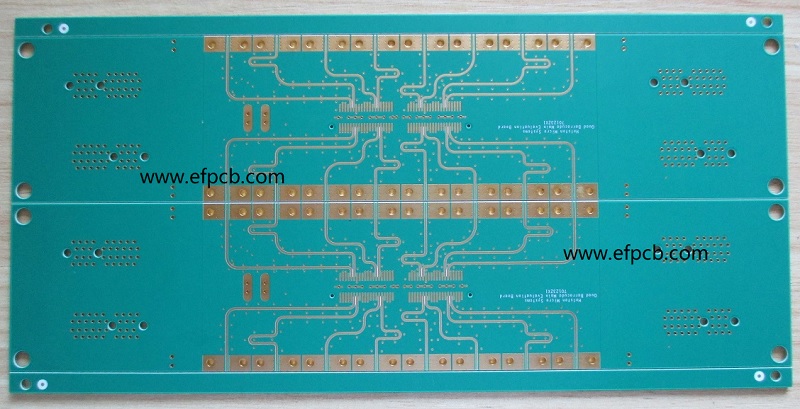

On account of various factors including miniaturization, PCB design is increasingly becoming a challenging task. But it is a fact that it needs to have a presence of digital, mixed as well as radiofrequency or what is popularly known as RF signals. In PCB manufacturing, Radio Frequency PCB is one of the fastest-growing sectors.

For RF PCBs, you require a whole new approach to layout as well as routing. In fact, for RF PCBs, it becomes necessary for you to look at the entire circuit as a distributed parameter system. During PCB Fabrication, PCB Designers face a lot of challenges. When it comes to RF PCBs two major challenges that designers face include:

- Capacitive coupling between signals

- Electromagnetic Interference

Capacitive Coupling between Signals in Radio Frequency PCB Layout

Capacitive coupling also referred to as electrostatic coupling is the transfer of electric energy between two insulator-separated conductors. For example, when two copper traces are kept close to each other, there is a transfer of energy from one trace to the other. In the Radio Frequency PCB layout, 3 common ways to prevent capacitive coupling include:

Increasing in distance between traces- To the distance between terminals capacitance is inversely proportional. The more the distance, less is the capacitive coupling.

Shielding high frequency traces with a ground terminated copper strip- The ground strip acts as a shield and makes sure that the charge is prevented from coupling to other traces.

You need to keep the traces short, as long traces will increase the area of the conductor, which in turn increases capacitive coupling.

Electromagnetic Interference (EMI)

Electromagnetic interference (EMI) is electromagnetic energy that in an electronic device through radiation or induction disrupts the signaling. Electromagnetic interference (EMI) is all around us starting from the static on the radio, to that buzz we hear when you bring a cell phone near audio equipment.

It is the electromagnetic compatibility or EMC, which is the ability of the electronic system to operate within an electromagnetic environment satisfactorily without even generating intolerable EMI that Radio Frequency PCB needs to aim for. EMI dominates the system performance when a device deviates from defined standards. During the early phases of the PCB design, it becomes important to control EMI.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5PCB core raw material CCL

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact