The Importance of High-Speed PCB in Modern Electronics

Keywords: High Speed PCB

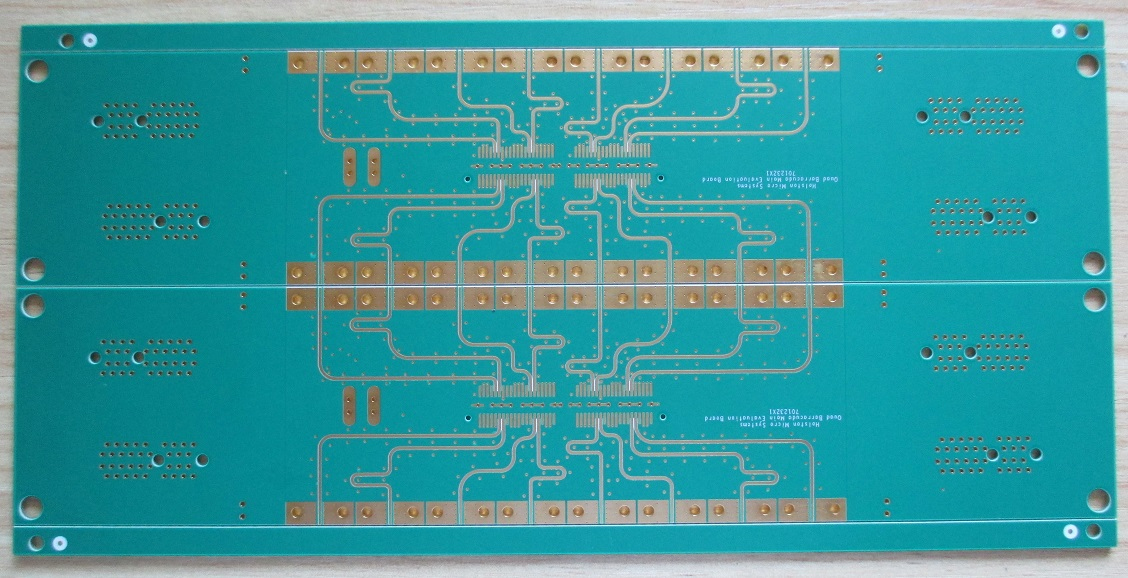

In today's fast-paced digital world, where technology continues to advance at an unprecedented rate, high-speed printed circuit boards (PCBs) have become the backbone of countless electronic devices. From smartphones and computers to advanced medical equipment and autonomous vehicles, high-speed PCBs play a vital role in ensuring the efficient and reliable operation of modern electronics. In this blog post, we will explore the significance of High Speed PCB and delve into their key benefits.

Data Transfer Rates

With the ever-increasing demand for faster and more efficient data transfer, high-speed PCBs are crucial components for achieving high data rates. Whether it's streaming high-definition video, transmitting large files, or facilitating real-time communication, these boards provide the necessary infrastructure to support lightning-fast data transfer between various electronic components and subsystems. By optimizing signal paths and reducing signal degradation, high-speed PCBs enable devices to process and exchange information at remarkable speeds.

Reduced Power Consumption

High Speed PCB designs incorporate advanced techniques to minimize power losses and maximize energy efficiency. By reducing parasitic capacitance and inductance, carefully selecting low-loss materials, and implementing intelligent power management strategies, these boards can help reduce power consumption in electronic devices. This becomes especially important in portable devices where battery life is a crucial factor. High-speed PCBs contribute to longer battery life and enhanced overall energy efficiency, making them indispensable for modern electronics.

Miniaturization and Design Flexibility

As technology continues to shrink in size, high-speed PCBs provide the necessary foundation for miniaturization without sacrificing performance. These boards are designed with compact and densely packed components, intricate signal routing, and advanced manufacturing techniques to accommodate the ever-reducing form factors of electronic devices. Moreover, high-speed PCBs offer design flexibility, enabling engineers to incorporate complex functionalities, multi-layered structures, and high-density interconnects. This flexibility paves the way for innovation and allows electronic devices to achieve new levels of performance and functionality.

Reliability and Manufacturing Efficiency

High Speed PCB undergoes stringent design and testing processes to ensure their reliability and manufacturability. These boards are subject to rigorous signal integrity simulations, thermal analysis, and electrical testing to verify their performance under various operating conditions. By employing high-quality materials, advanced manufacturing techniques, and robust design principles, high-speed PCBs exhibit enhanced resistance to environmental factors, temperature fluctuations, and mechanical stress. This results in increased product reliability, reduced failure rates, and improved manufacturing efficiency.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5Top HDI PCB Manufacturers (2024)

- 6PCB core raw material CCL

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact