The Mysteries of PCB Prices: The Factors that Influence Costs

Keywords: PCB Price

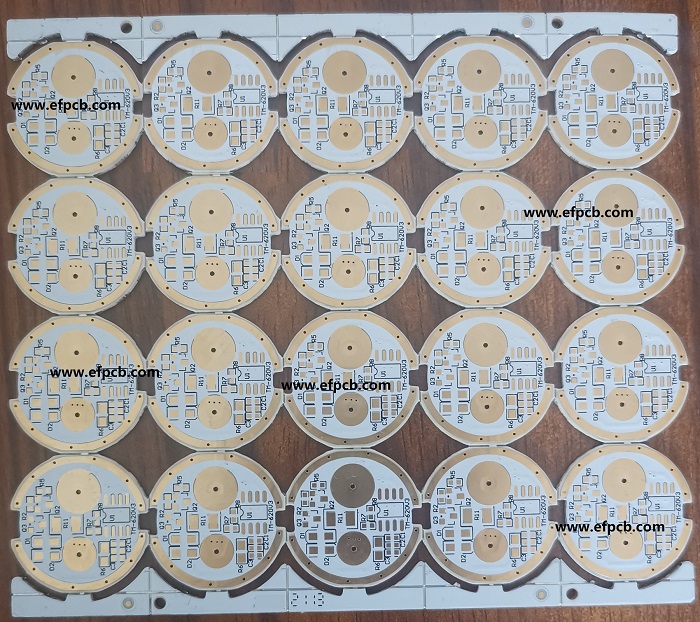

Printed Circuit Boards (PCBs) are the backbone of modern electronics, acting as the platform for connecting various electronic components. When it comes to developing electronic devices or prototypes, understanding the factors that contribute to PCB Price is crucial. In this blog, we'll explore the key elements that influence PCB costs, helping you gain a deeper understanding of the pricing dynamics in the PCB industry.

Design Complexity

One of the primary factors that affect PCB prices is the complexity of the design. PCBs with intricate circuitry, multiple layers, and densely packed components require more advanced manufacturing techniques, increasing production costs. Complex designs demand additional processing steps, longer manufacturing times, and higher precision equipment, all of which contribute to higher prices. Conversely, simpler PCB designs with fewer layers and basic routing configurations tend to be more cost-effective.

Materials Used

The choice of materials significantly impacts PCB prices. Various factors, including substrate material, copper weight, and finish, influence the overall cost. FR-4 (Flame Retardant 4) is the most common substrate material due to its affordability and versatility. However, higher-grade materials such as Rogers, which offer improved electrical properties and heat dissipation, come at a premium price. Similarly, thicker copper weights or special finishes like gold plating for better conductivity can increase costs.

Quantity and Order Volume

PCB prices are also influenced by the quantity and order volume. Manufacturers often offer price breaks for larger quantities due to economies of scale. Bulk orders allow manufacturers to optimize production processes and reduce material wastage, resulting in lower costs per unit. Conversely, smaller quantities or one-off prototypes tend to have higher prices, as they require additional setup time and involve a less streamlined manufacturing process.

Turnaround Time

Urgency can impact PCB prices as well. If you need your PCBs manufactured and delivered quickly, manufacturers may charge a premium for expedited services. Rush orders often require rearranging production schedules, reallocating resources, and working overtime, all of which contribute to higher costs. Planning and allowing for longer lead times can help mitigate these additional expenses.

PCB Size and Layer Count

The physical dimensions and layer count of a PCB affect its price. Larger PCBs require more material, increased fabrication time, and more extensive quality control checks, resulting in higher costs. Similarly, multi-layer boards with intricate layer stacking configurations can be more expensive to manufacture due to the added complexity and increased processing steps.

Additional Features

PCB prices may vary based on additional features or customizations. Advanced features like blind and buried vias, impedance control, and controlled dielectric constants require specialized manufacturing techniques and equipment, resulting in higher costs. Similarly, specific testing requirements, such as flying probes or in-circuit testing, can contribute to increased prices. It is essential to consider whether these features are necessary for your application or if simpler alternatives can fulfill your requirements more cost-effectively.

Manufacturing Location

The geographic location of the PCB manufacturer can impact the pricing as well. Manufacturing costs and labor rates vary across different regions and countries. Manufacturers located in countries with lower labor costs may offer more competitive prices. However, it's essential to consider factors such as quality standards, communication, and shipping costs when choosing a manufacturing location. Offshore manufacturing may have lower upfront costs, but additional expenses like import taxes, shipping, and potential delays can offset the initial savings.

Supplier Selection

The choice of PCB supplier also influences the pricing. Working with a reputable and reliable supplier is crucial to ensure quality and timely delivery. While some suppliers may offer lower prices, it's important to assess their track record, certifications, and customer reviews to ensure they meet your quality standards. Establishing a long-term relationship with a trusted supplier can result in better pricing and additional benefits like technical support and efficient customer service.

Market Conditions

PCB Price can also be influenced by market conditions and industry trends. Factors such as supply and demand, availability of raw materials, and global economic factors can impact pricing. During periods of high demand or material shortages, PCB prices may increase due to limited supply and increased competition. Staying updated with market trends and collaborating with your supplier to analyze market conditions can help you make informed decisions and adjust your purchasing strategy accordingly.

Quality Assurance

Ensuring high-quality PCBs is vital for the reliability and performance of your electronic devices. PCB manufacturers that prioritize quality assurance invest in advanced testing methods, quality control processes, and adherence to industry standards and certifications. While this commitment to quality may contribute to slightly higher prices, it is crucial to prioritize reliability and long-term performance over short-term cost savings.

Value-added Services

Some PCB manufacturers offer value-added services that can impact pricing. These services may include design for manufacturability (DFM) reviews, design optimizations, and engineering support. While these services may come at an additional cost, they can result in improved overall product quality, reduced manufacturing errors, and optimized production processes. Collaborating with a manufacturer that provides value-added services can save costs in the long run by avoiding design iterations, ensuring efficient manufacturing, and minimizing the risk of costly rework.

Environmental and Regulatory Compliance

Environmental and regulatory compliance requirements can also influence PCB prices. Manufacturers that adhere to stringent environmental standards and certifications, such as RoHS (Restriction of Hazardous Substances), may invest in eco-friendly production processes and materials. These additional measures can contribute to slightly higher costs but align with sustainable practices and ensure compliance with global regulations. It is essential to work with manufacturers who prioritize environmental responsibility and can provide the necessary documentation and certifications to meet your project's compliance requirements.

Volume Agreements and Contracts

For long-term or high-volume PCB production, entering into volume agreements or contracts with manufacturers can result in cost savings. These agreements establish a mutually beneficial relationship where the manufacturer provides preferential pricing, dedicated resources, and streamlined production processes. By committing to a certain volume over an extended period, you can negotiate favorable terms and achieve better economies of scale, ultimately reducing the overall PCB prices.

Market Competition

The competitive landscape within the PCB industry can also impact pricing. Manufacturers strive to offer competitive prices to attract customers and maintain market share. It is advisable to research and obtain quotes from multiple suppliers to compare pricing and ensure that you are getting a fair price for your PCB requirements. However, it's important to balance cost considerations with other factors such as quality, reliability, and customer service to make an informed decision.

Conclusion

Understanding the factors that influence PCB Price is crucial for optimizing costs without compromising quality. Design complexity, material choices, quantity, turnaround time, PCB size, and additional features all play a significant role in determining the final price. By considering these factors during the design and planning stages, you can make informed decisions that align with your budget and project requirements. Collaborating closely with a reputable PCB manufacturer can further help you navigate the price dynamics and find the best balance between cost, functionality, and quality in your PCB development journey.