The Real Significance of Printed Circuit Boards for Electronics

Keywords: Printed Circuit Board, Printed Circuit Board Manufacturer

The majority of electrical gadgets are built around a Printed Circuit Board. What exactly is a PCB, though? You'll find them in anything from your phone to your computer. Let's examine the numerous features of this sophisticated technological device and discuss their significance.

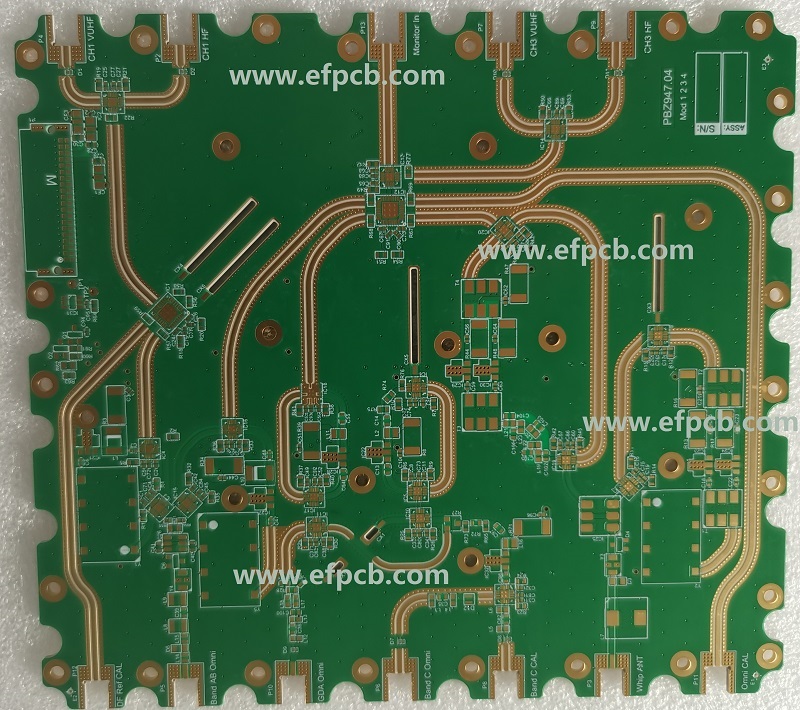

Printed circuit board

A printed circuit board, or PCB for short, is an electronic board containing integrated metal circuits that link various parts of the apparatus. It is made up of layers that are first individually etched, then laminated to create patterns called traces.

These patterns represent the paths taken by signals as they move around the circuit board and transfer data between various components.

Depending on their intended application, the boards come in a variety of sizes and forms; some have holes punched into them, while others may simply require little pads to connect components.

Solder pads, which come in through-hole and surface mount varieties, are used to join the electronics constructed on PCBs to the board. In contrast to board-mounted devices, which are primarily SMDs, through-hole components contain wires or pins that run through drilled holes into the circuit board. Board-mounted components are secured to the board by melted solder.

Both methods of joining components have advantages and disadvantages, but SMDs are becoming widespread because they are smaller and quicker, while through-hole is becoming less used because of its size and weight.

Different Boards

There are a tonne of possibilities available if a PCB is what your next project calls for. There are single-layer boards, multi-layer boards, flexible PCBs, and stiff PCBs. FR4, a glass epoxy laminate, and CEM are just a few examples of the various materials that can be used. You can purchase them from companies that offer PCB Assembly services and place the necessary electronic components on the PCB. These service providers specialize in various areas, such as wireless technologies, embedded systems, or sensors.

Adaptable PCBs

These can be twisted over sharp edges without breaking and are constructed of silicone or polyimide.

The rigid-flexible type, which combines flexible and stiff PCBs, and the foldable type, which can be wrapped in half without breaking, are the two different varieties available.

Boards with a single layer and many layers

The number of layers on a board can also vary, with some having just one layer and others having as many as 16. A board gets more intricate the more layers there are interspersed among it.

However, additional functionality results from that complexity. Simple devices employ single-layer boards, and more complicated devices use multi-layer boards.

PCBs use

There are PCBs in almost every electrical gadget you can imagine. You name it: cell phones, laptops, tablets, TVs, even automobiles.

A PCB's primary purpose is to link and enable communication between various device components.

For instance, the PCB in your phone links the circuits in the back, the buttons, and the display. These parts couldn't communicate with one another without this board, and the phone would stop working as a result.

Additionally crucial in preventing damage to these components are PCBs. They are shielded from external interference like electromagnetic radiation by being mounted on a board and covered with layers of metal.

The Advantages of PCBs

The utilization of printed circuit boards has several advantages.

- The primary benefit is that they make items more portable and smaller.

- You may create a product that is substantially smaller by using circuits on a PCB from a Printed Circuit Board Manufacturer rather than individual components alone. This also makes it simpler to assemble various components of your circuit and route traces in the appropriate directions.

- They are also incredibly strong and long-lasting. They can withstand a great deal of harm, including heat, wetness, and even physical force, without disintegrating. This makes them perfect for usage in environments that are dangerous for electronics, such as the region under the hood of a car where they are exposed to substances like water and oil.

- It is essential to allow the boards to resist these conditions to guarantee that it keeps functioning effectively, especially if it's anything significant like braking systems.

- Thirdly, they are quite secure. A PCB's circuitry is enclosed, making it nearly difficult to touch two connections at once with naked skin. By doing this, you have no risk of receiving an electric shock from your gadget.

- Fourthly, PCBs are incredibly effective and affordable. They enable the creation of devices using fewer components, which reduces costs for both you and your company.

- And last, PCBs are simple to recycle and repair. In most cases, it is significantly simpler to repair a board-level component failure than it would be if it occurred elsewhere in the circuit. Additionally, recycling the board when it inevitably reaches the end of its useful life won't have any detrimental impact on the environment.

They Maintain Device Coolness

PCBs' capacity for cooling is another crucial feature. Heat is produced by every component in a circuit, and if this heat is not controlled, it might harm your gadget. A PCB's metal layers reflect and transfer heat away from its producing components.

Thus, overheating is avoided and your gadget is kept operating at peak efficiency for as long as feasible. Electronics failure is frequently brought on by overheating; therefore keeping them cool lengthens the useful life of your device.

They do, however, make it more difficult to effectively transmit heat out from the interior of your gadget while simultaneously keeping things cold. This is due to the metal layers' insulating properties, which stop heat from radiating outward.

Although there are workarounds available, such as thermal vias (which join two or more metal layers with conductive material), it's not always possible.

The ability to operate modern products would be lost without printed circuit boards. They are crucial for establishing connections between various elements and enabling communication between them. PCBs also assist in shielding these components from harm and interference.

It's crucial to have a PCB component that can meet demand in a world where everything is getting more and more electronic.

Take a moment to admire the underlying Printed Circuit Board that is enabling your phone or computer the next time you use it.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5Top HDI PCB Manufacturers (2024)

- 6IC Substrate | Comprehensive Guide (2021)

- 7Top 10 Flexible PCB Factories in 2025

- 8How to Make mSAP PCB?

- 9The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 10Top 10 IC Substrate Fabricators (2024)

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact