The Revolution of Flexible PCBs: Unlocking New Horizons

Keywords: Flexible PCB

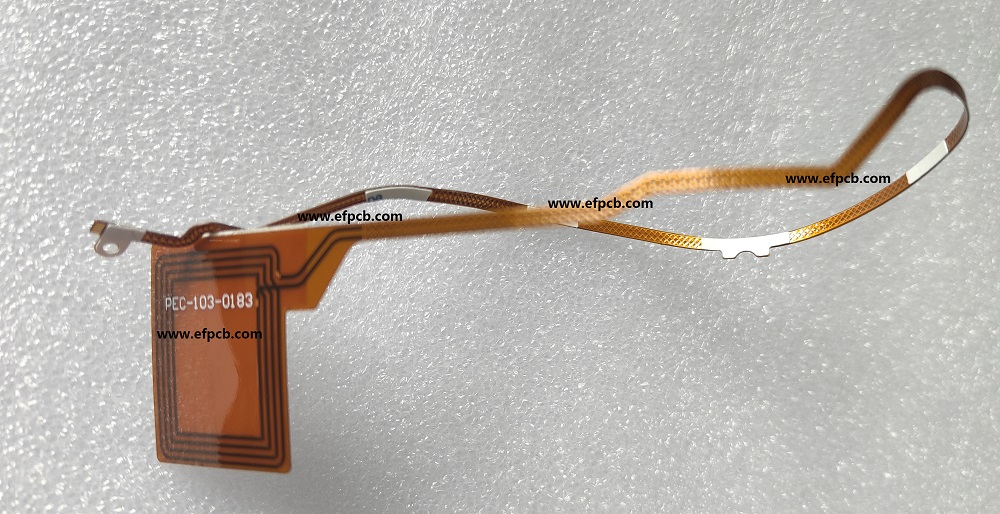

Flexible PCB, also known as flex circuits or flex boards, is a groundbreaking advancement in the field of electronics. Unlike traditional rigid PCBs, which are made from inflexible materials like fiberglass, flexible PCBs are manufactured using thin and flexible substrates such as polyimide (PI) or polyester (PET). These substrates allow the circuits to bend, twist, and conform to different shapes and spaces, enabling the design and creation of innovative electronic products.

Benefits of Flexible PCBs:

- Space-saving and lightweight: Flexible PCBs are exceptionally thin and lightweight, making them ideal for applications where size and weight are critical factors. They can be seamlessly integrated into compact devices and wearable electronics, offering designers greater freedom and flexibility in their designs.

- Enhanced Reliability: The flexible nature of these PCBs eliminates the need for numerous interconnects and connectors that are typically required in rigid boards. With fewer components, the chances of failures due to loose connections or vibration-induced damage are significantly reduced. Flexible PCBs also excel in environments with high shock and vibration, making them more reliable and durable than their rigid counterparts.

- Improved Signal Integrity: The flexible substrate materials used in the Flexible PCB have excellent electrical properties, such as low dielectric loss and controlled impedance. This allows for better signal transmission, reduced signal loss, and improved overall performance of electronic devices. The elimination of connectors and shorter signal paths further enhances signal integrity and reduces electromagnetic interference (EMI).

- Design Freedom: Flexible PCBs offer unprecedented design freedom, enabling engineers to create products with unique form factors and intricate layouts. They can be bent, folded, or twisted to fit into irregular shapes or tight spaces, opening up a world of possibilities for innovative designs.

Applications of Flexible PCBs:

Consumer Electronics: Flexible PCBs are extensively used in smartphones, tablets, smartwatches, and other portable devices. Their ability to conform to curved surfaces and accommodate complex layouts makes them invaluable in the consumer electronics market.

Medical Devices: Flexible PCBs find applications in medical devices such as pacemakers, hearing aids, and medical implants. Their flexibility and biocompatibility make them suitable for conforming to the contours of the human body and delivering precise electrical signals.

Industrial and IoT Applications: Flexible PCB is utilized in industrial automation, Internet of Things (IoT) devices, and sensors. They can withstand high-temperature environments, accommodate dynamic movement, and provide connectivity in challenging conditions.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5Top HDI PCB Manufacturers (2024)

- 6PCB core raw material CCL

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact