The Technique and Importance of PCB Assembly

Keywords: PCB Assembly China, PCBA Assembly China

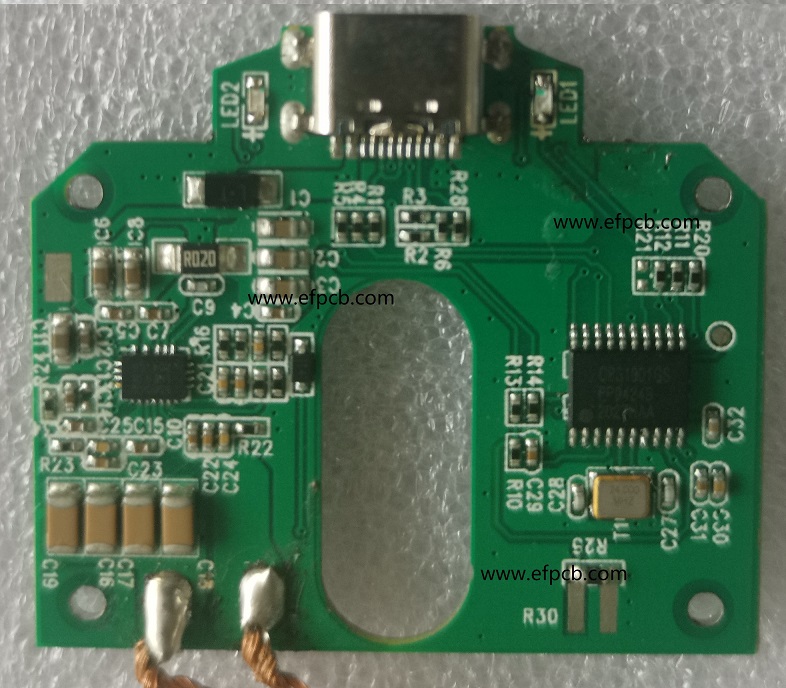

The process of connecting various electronic parts to a printed circuit board to create and finish a completely working PCB Assembly China is referred to as printed circuit board assembly. The two construction styles that are essentially used in this procedure are surface-mount construction and through-hole construction. When used, each of these techniques has advantages. While through-hole mounting offers robustness for any component that is likely to experience physical stress in the unit; surface mounting takes up less space. However, each of these approaches has pros and cons when it comes to the crucial process of assembly.

Assembly: Using various conductive paths, techniques, tracks, and traces, PCBs are used to directly connect and support a variety of electrical components. These parts are etched from copper sheets that have been bonded onto a non-conductive substrate. Additionally, this assembly is created by attaching electrical components after the whole PCB process is finished. Electronic components are mounted on the printed circuit board's external pads after the component leads are properly threaded through the PCB and surface mount construction holes. Finally, in both versions of this structure, the component leads are mechanically fastened to the PCB with the use of soft metal solder.

Various ways are used throughout the assembly process to attach the components to this. If a huge volume of goods needs to be produced, bulk wave soldering, machine placement, or the use of reflow ovens are typically used. Even a mechanical PCBA Assembly China service specialist can build the assembly unit utilizing the techniques and supplies mentioned above.

Because of their practicality and efficiency in today's electrical and technical environment, printed circuit board assembly solutions are the most significant component of the electronics industry. An electronic component known as a printed circuit board is used to link electrical components in a variety of machines and gadgets.

What Do PCB Assembly Benefits Mean?

These gadgets are essential since they can easily upgrade any electrical equipment or gadget. The process of joining different electrical parts to a printed circuit board to create and finish a completely functional printed circuit assembly is referred to as prototype PCB assembly. Surface-mount construction and through-hole construction are the two forms of construction that are used in the process of PCB Assembly China.

- 1HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 2HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 3Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 4PCB core raw material CCL

- 5IC Substrate | Comprehensive Guide (2021)

- 6Top HDI PCB Manufacturers (2024)

- 7How to Make mSAP PCB?

- 8The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- 9Top 10 Flexible PCB Factories in 2025

- 10Top 10 IC Substrate Fabricators (2024)

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact