Thermal Vias Enhances Thermal Management in RF PCBs

Keywords: RF Microwave PCB

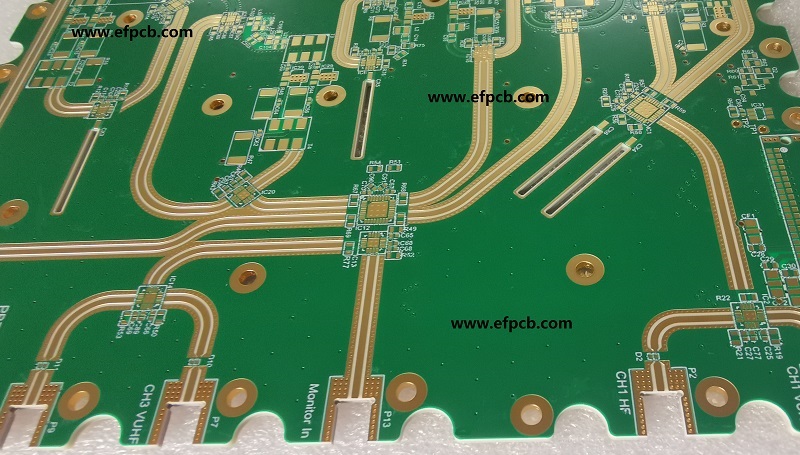

RF PCBs are specialized printed circuit boards designed to handle high-frequency signals. These boards are found in various applications, including wireless communication devices, radar systems, satellite communication, and more. Due to the high-frequency nature of RF signals, the RF Microwave PCB often contains components that generate significant heat, such as power amplifiers, RF transceivers, and RF power combiners.

Thermal Challenges in RF PCBs

- Signal Integrity: Elevated temperatures can change the dielectric properties of the PCB material, affecting signal propagation and phase stability.

- Component Reliability: Excess heat can reduce the lifespan of RF components, leading to premature failures and increased maintenance costs.

- Frequency Drift: Temperature-induced variations can cause frequency drift in RF circuits, impacting their ability to maintain accurate and stable frequencies.

To address these challenges, RF Microwave PCB designers employ various techniques, with thermal vias and heat sinks playing a crucial role.

Thermal Vias: The Heat Dissipation Pathway

Thermal vias are small copper-plated holes strategically placed within the PCB to provide a pathway for heat to escape from the components to the outer layers of the board. These vias connect the top and bottom copper layers, allowing heat to spread and dissipate more effectively.

How do thermal vias work?

- Heat Conduction: When a component generates heat, the thermal vias conduct this heat away from the component and into the underlying copper layers.

- Heat Spreading: The heat is then distributed through the copper layers, spreading it over a larger area of the PCB.

- Heat Dissipation: Finally, the heat is dissipated into the surrounding environment through conduction, convection, and radiation.

Heat sinks: Enhancing Heat Dissipation

While thermal vias provide an effective means of heat conduction within the PCB, heat sinks offer an additional layer of cooling. Heat sinks are metallic components, typically made of aluminum or copper. These are attached to hot components to increase the surface area available for heat dissipation.

How do heat sinks work with thermal vias?

- Contact with Hot Components: Heat sinks are attached directly to RF Microwave PCB components like power amplifiers or voltage regulators, which tend to generate more heat.

- Increased Surface Area: The heat sink’s fins or protrusions increase the surface area exposed to the air, facilitating efficient heat transfer.

Enhanced Cooling: Heat generated by the component is conducted into the heat sink, and airflow helps dissipate it, keeping the component temperature within an acceptable range.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5PCB core raw material CCL

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact