Understanding Hard Gold Plating PCB Manufacturing

Keywords: Hard Gold PCB

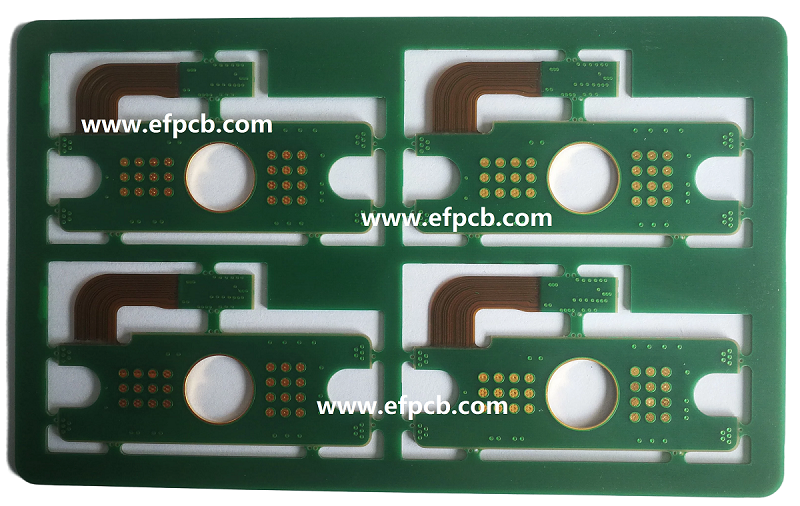

Hard Gold is commonly plated onto printed circuit boards to provide contact points and Hard Gold PCB edge connections. On circuit boards with membrane switches, a preferred technology for commercial, industrial, and consumer devices, gold contact surfaces are frequently employed. Edge-connector contacts, sometimes called Gold fingers or electroplated gold contacts, are utilized when PCBs will be mounted and withdrawn repeatedly.

The strong gold plating needed for both contacts and gold fingers can be produced internally by manufacturers.

Following the copper etch, the PCB tape is laminated to only leave the required region exposed. The 24-carat hard gold is then electroplated directly onto the nickel surface after being submerged in a salt medium.

An example of a PCB surface treatment is plating, commonly referred to as nickel gold electroplating. Placing gold involves electroplating a layer of gold over a nickel barrier coat during the PCB manufacturing process.

There are two types of gold plating: hard gold plating and soft gold plating. When developing PCBs, the PCB producer must take the characteristics of the two kinds of gold into account.

Application of plating gold in PCB manufacture

Hard gold plating is appropriate for usage in areas where frictional force is required, such as gold fingers and keypads. On COB, soft gold is often utilized for wire made of aluminum or gold (Chip On Board). Hard gold finishes are subject to thickness and tape adhesion tests as part of quality control.

A coating of gold with additional hardeners for improved durability is plated over a barrier coat of nickel using an electrolytic technique to create the Hard Gold surface finish, also known as Hard Electrolytic Gold. Due to the high cost of hard gold and its relatively poor solder ability, it is only very rarely applied to solder-able areas during PCB fabrication. Hard gold is extremely durable, so during this process, it is typically applied to high-wear areas, such as edge connector Gold Fingers and keypads, since the finish's hardness can withstand repeated use.

Full body Hard Gold is a seldom selected surface treatment in which the entire PCB board is hard gold-plated. Depending on the PCB design, either an immersion method or an electrolytic process must be used to apply a full-body Hard Gold PCB surface finish.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4PCB core raw material CCL

- 5Top 10 Flexible PCB Factories in 2025

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact