Leading Top 10 Rigid Flex PCB Manufacturers in 2025

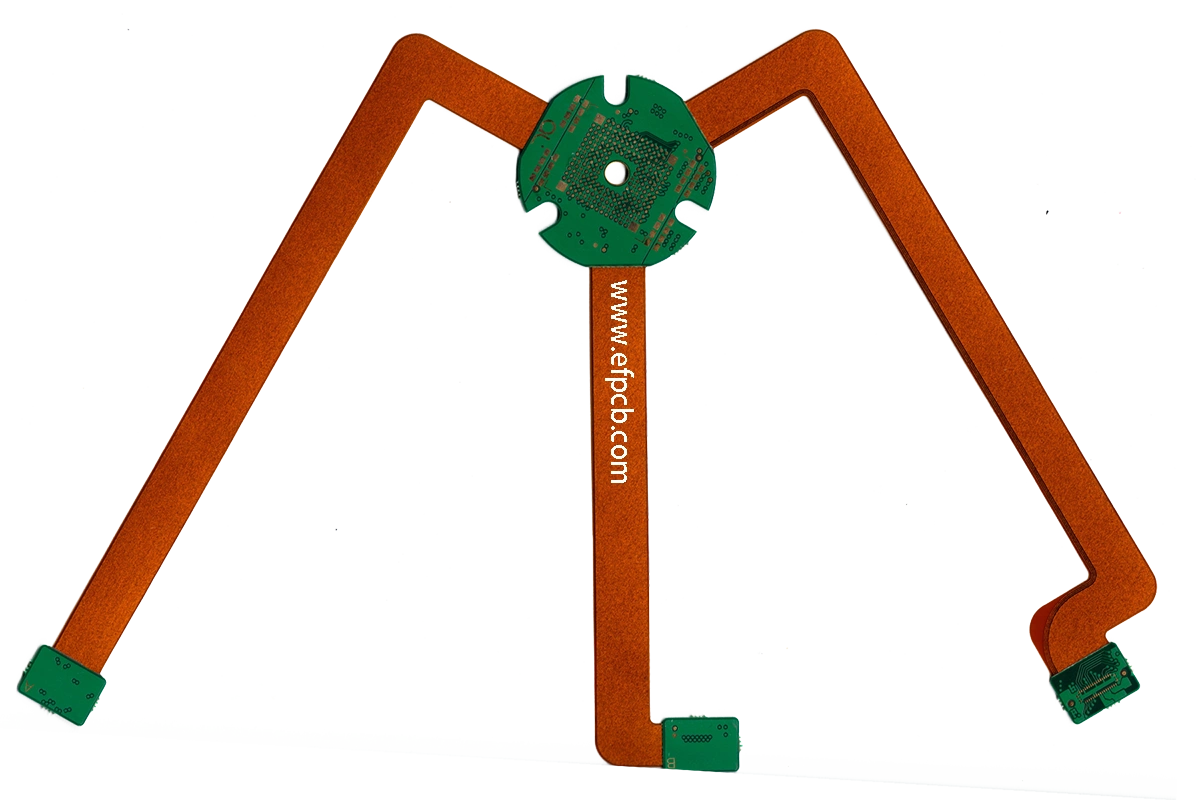

As electronic equipment becomes more complex and miniaturized, the need for more advanced circuit board solutions is rising. Rigid flex PCBs are high quality, multilayer flexible PCBs attached to rigid boards, are leading this technological advancement. Selection of the appropriate manufacturer in for 2025 is important to ensure product quality, performance and timely delivery. This article focuses on the top 10 global Rigid flex PCB manufacturers based on their production process expertise, innovation and industry leadership.

Benefits of Rigid flex PCB Manufacturing

Rigid flex PCB manufacturers provide solutions for high-end electronics that include smartphones and tablets, medical instruments, aerospace electronics, and automotive parts. The special features of rigid flex PCBs, such as multilayer PCBs and 3D structures are due to the combination of rigid and flex layers that allow the creation of three dimensional circuit designs, which in turn produces a reduced weight design that is highly durable. Advanced rigid flex PCB manufacturer with modern equipment and rich experience can meet all your rigid flex PCB needs perfectly and deliver the orders in satisfaction.

Survey of the Rigid Flex PCB Production Process

Prior to delving into the best manufacturers, here’s a primer on the processes that makes a top rigid flex PCB manufacturer:

Material Selection: The quality of the material is the basis of any high-performance rigid-flex PCB. High quality polyimide films are used by manufacturers for the flexible layers and FR-4 or other sturdy materials are used for the rigid layers. The selection of adhesives and copper foils is also very important for the durability of signal so that integrity is guaranteed.

Imaging and Patterning: High precision imaging is necessary for generating complicated circuit patterns. Top producers utilize high-precision laser direct imaging (LDI) technology to produce fine lines and spaces so as to meet the demands of high density interconnect.

Layer Lamination: Rigid layers and flexible layers are stacked together by the method of sequential lamination. It is a meticulous process of alignment and heating to make certain that the flexible components stay solid and usable. To achieve uniformity in volume, high throughput automated lamination presses utilized.

Drilling and Via Formation: Micro via and through hole drilling are performed with laser and mechanical drills. These holes are plated with copper to provide electrical connection between the layers of the PCB. The precision of this process is what sets apart a superior quality rigid flex PCB manufacturer.

Solder Mask and Surface Finishing:

A solder mask is sprayed to cover the circuitry and then surface finishes, such as ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderable Protective Layer), are applied to improve solderability and the life span of the PCB.

Testing and Quality Control:

All boards are subjected to rigorous electrical and functional tests. To make sure only the perfect products are shipped, there are automated optical inspection (AOI), x-ray examination, flying probe test.

10 Best Rigid Flex PCB Manufacturers in 2025

Although the industry is highly competitive, the following rigid flex PCB manufacturers have been leading the industry since 2025 due to their innovative capabilities, production capacities and global reputation:

1. TTM Technologies

TTM Technologies was founded in Denver, Colorado and it is a world leader with sophisticated manufacturing lines in Aerospace/Defense/Medical in rigid flex PCB.

2. High Quality PCB

With expertise in high density rigid flex PCBs, is a global provider in advanced manufacturing technology, high reliable and quick prototyping solutions, the shortest leadtime 5 working days for urgent prototypes, 2-3 weeks for your mass production orders.

3. Zhen Ding Technology

Zhen Ding as the world’s largest PCB manufacturer is also famous for its rigid flex PCB production, excellent high volume, high reliability manufacturer for consumer electronics and automotive etc.

4. Nippon Mektron

A leader in flexible and rigid flex circuit innovation, provides the leading brands in smartphones and wearables with ultra-thin high-performance boards.

5. Sanmina Corporation

With its global verti-cal integration, Sanmina provides full turnkey rigid flex PCB solutions for the med and industrial and telecom markets.

6. Sumitomo Electric Industries

Sumitomo Electric has been at the forefront of advanced materials and microvia technology in support of next-generation semiconductor packaging and automotive electronics.

7. Multek (A Flex Company)

Multek’s capability in rigid flex PCB production is demonstrated by very high yields and precision in manufacturing of a wide range of applications such as IoT, mobile and medical devices.

8. Shennan Circuits

Shennan Circuits is a Chinese company combining mass production with strict quality control to supply the high-reliability industry worldwide.

9. Interflex

Specialized in flexible and rigid flex products, Interflex is a leading supplier to the display and automotive industry.

10. AT&S

AT&S is a technology leader, known for its innovation-driven culture, and the complexity of its products, the high-tech rigid flex PCBs for the industrial, medical, communication systems. With a reputation for quality, reliability, and innovation, these are the best rigid flex PCB manufacturers you can trust.

Common Questions

What should I look for when selecting a rigid flex PCB manufacturer?

Choose a vendor with a good reputation, high-end production equipment, sound quality assurance system and rich industry experience. ISO 9001, IPC standards are related also to the quality.

How do rigid flex PCB manufacturers guarantee the reliability of their products?

This is achieved by the selection of appropriate materials, accurate imaging and drilling, comprehensive testing, and rigorous process controls throughout manufacturing.

Is there a cost variance in rigid flex PCB manufacturer?

Yes, prices may depend on the geographic region, volume, complexity of technology, and other services offered such as design assistance or rapid prototyping. Nevertheless, the quality and reliability of the product are paramount over price alone.

Do rigid flex PCB manufacturers provide quick-turn or prototype service?

Top manufacturers do provide quick-turn and prototyping services through utilizing CNC and automated systems in order to meet demanding turnaround times without sacrificing quality.

Which are the top industries expected to drive the growth of a leading rigid flex PCB manufacturer?

Aerospace and defense, medical devices, automotive, telecommunications, consumer electronics – these are a handful of the industries dependent on expertise of the world’s leading rigid flex PCB manufacturers where mission critical applications are the norm not the exception.

How do producers of rigid flex samples tackle environmental issues?

Top manufacturers of rigid flex PCBS utilize green initiatives such as waste stream reduction, recycling, and RoHS and REACH compliant protocols to be environmentally responsive.

Can you tailor your rigid flex PCB designs with these manufacturers?

Absolutely. Leading rigid flex PCB manufacturers can tailor to your requirements such as different stack-ups, special materials, and customized testing etc. to fulfill unique needs from customers. With a good rigid flex PCB manufacturer on their side, companies can be confident that their electronic products will perform well and last long in a challenging market environment.

NEW ARTICLES

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5PCB core raw material CCL

- 6Top HDI PCB Manufacturers (2024)

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact