Top HDI PCB Manufacturers (2024)

HDI PCB is short name for High Density Interconnect Printed Circuit Board. HDI PCBs are the leading edge in modern electronics technology, providing more compact design, limited signal distortion and better performance. With industries like telecommunication, automotive, healthcare and consumer electronics demanding small size and high-performance devices manufacturers have become crucial part in global supply chains. Laura provides the leading HDI PCB manufacturers in 2024 to analyze their product characteristics, technological innovation and market presence.

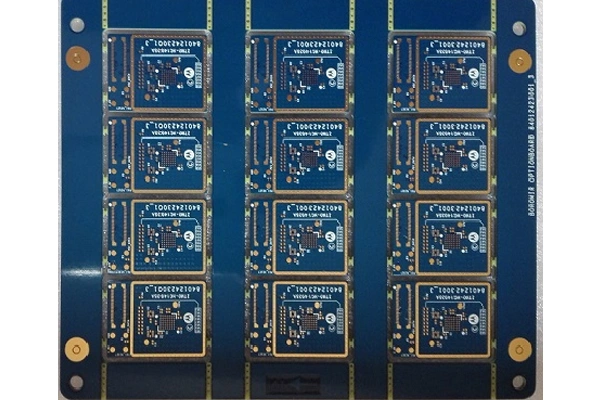

THE LEADING EDGE OF INNOVATION – HDI PCB MANUFACTURERS

Higher wiring densities, more microvias and thinner build-ups — HDI PCBs are the best option when your project calls for a tighter more lightweight design. The manufacturers use sophisticated fabrication methods to make boards with finer line widths, smaller via holes, and more layer connections. These are used in high-end 5G, IoT, auto electronics and medical devices where performance and reliability is crucial.

The Important Aspects of HDI PCB Manufacturers Products

The demands of modern electronics have resulted in HDI PCB manufacturers developing specialized technology and designs. The following is what you demand to know about them.

1. Microvia Technology

Microvias are what differentiate HDI PCBs, and allow connections between layers through smaller holes. By using HDI PCB manufacturers can use laser drilling to create microvias as small as 50 microns or 2 mil, if you will, so that your high density trace patterns to be interconnected.

2. High Layer Counts

High Density Interconnected PCBs are commonly designed with multiple layers for complex circuit layouts. Major manufactures offering HDI PCBs can offer up to 20 layer boards to allow better routing space for demanding solutions.

3. Fine Line/Space

So that these constrained outlines can be met, line/space measurements of HDI PCB producers are regularly as thin as 2 mils (0.05 mm), permitting the setup to fit together firmly to encourage rapid signal transmission. It is this precision that is required in applications like smartphones and wearable devices.

4. Advanced Materials

HDI PCB manufacturers use high-quality materials like low-loss dielectrics, high-temperature laminates, and copper-clad laminates to achieve reliable and high-performance solutions. These new materials, which boost signal integrity and thermal performance.

5. Stacked and Staggered Vias

Stacked and Staggered Vias: HDI PCB manufacturers use stacked and staggered vias to connect the different layers robustly. These methods help to increase mechanical stability and transformers while boosting their electrical performance characteristics, particularly at high-frequency applications.

6. Impedance Control

For high-speed circuits impedance control is critical to signal integrity. Adapted impedance throughout the whole board — quality of HDI PCB manufacturers: Advanced design and fabrication techniques guarantee you a consistent impedance across the entire board.

Main HDI PCB Manufacturers in 2024

1. TTM Technologies

If you want to work with the high-quality and innovative fabrication of HDI PCBs then TTM Technologies is your number one choice. It accommodates microvia technology in ultra-fine line widths and a high layer count of PCB production. The company's products are used in aerospace, automotive and telecom applications.

2. High Quality PCB Co., Limited

High Quality PCB is a global leader in HDI PCB manufacturing and a one stop shop for all of your HDI needs for 5G, IoT, and automotive electronics. From HDI PCB design, layout, manufacturing, components purchasing to PCB assembly, boxing, testing. Their advantages are fast delivery or quick turn (4 to 10 working days) for prototypes, short time (3 to 4 weeks) for mass production. The High Quality PCB is very devoted to sustainability, has led the company to implement environmentally friendly processes.

3. AT&S (Austria Technologie & Systemtechnik)

AT&S — European HDI PCB manufacturer for high-density boards used in Medical, Automotive, Industries. The products have tight fine line and space dimensions, as well advanced impedance control that are also required for high speed applications.

4. Compeq Manufacturing Co., Ltd.

Compeq is a huge brand in Asia and specializes in the production of high-quality innovative HDI PCB designs. The firm uses stacked and staggered vias for robust interconnection and mechanical strength in its products. AMOLIN announced that COMPEQ has focused on the further miniaturization of electronic components and received large orders from major consumer electronics manufacturers.

5. Tripod Technology Corporation

HDI PCBs for telecommunications, automotive and consumer electronics — Tripod Technology The company uses high layer boards in combination with extreme materials making the boards perfect for compact designs, dependable performance. One of the areas where Tripod has invested is in automation and AI-driven quality control.

6. Zhen Ding Technology Holding Limited

Zhen Ding: A major HDI PCB producer based in Asia and North America. Its products, which include ultra-thin designs and high-density interconnections, are used in smartphones, tablets and wearable devices. Regular innovation at Zhen Ding R&D is the priority

7. Multek

At Multek, we have a strong track record of HDI PCB manufacturing and capabilities in high-frequency applications. Low-loss dielectrics and precision impedance control also highlight the capabilities of the company's boards 5G and IOT devices. This dedication to sustainability is recognized in its deployment of environmentally responsible materials by Multek.

8. Advanced Circuitry International (ACI)

ACI is an HDI / High Frequency PCB Format, Rigid-Flex Laminate Material & Fill Insulator for aerospace, military and telecommunication applications. The company’s products boast strong thermal management and high layer counts, providing increased reliability in harsh environments. As a result of this dedication to quality, ACI is well known for being the trusted HDI PCB manufacturer.

9. Nan Ya PCB Corporation

With specialization in memory chips, processors, and consumer electronics, Nan Ya PCB Corporation is among the top HDI PCB manufacturers. This implies that the company's boards with fine line widths and advanced materials all support high-speed signal transmission and thermal stability. Nan Ya's investment in automation ensures production efficiency.

10. MFlex (Multi-Fineline Electronix)

MFLEX, the HDI PCBs Manufacturer of Flexible and Flexi-Crash Board in Global Its products are defined by ultra-thin form factors and high-density interconnect, underscoring their suitability for small devices like smartphones and wearable devices. As a supplier for emerging technologies, MFlex is concentrating on innovation.

Innovations Propelling HDI PCB Manufacturers in 2024

Miniaturization

Smaller electronic devices require HDI PCB suppliers to produce extra thin boards with even finer line widths and higher numbers of layers. Leading manufacturers are employing sub-2-mil line/space technology as the norm, which leads to compact and highly efficient designs.

High-Frequency Performance

As 5G and IoT become more common, HDI PCB makers are interested in materials that enable high-frequency signal transmission. Dielectrics that have low loss in the RF/MWs and advanced laminates are also needed to ensure signal quality at high speeds.

Sustainability

All this means that HDI PCB manufacturers are increasingly paying attention to environmental sustainability. In order to limit their own environmental impact, and also comply with the increasingly stringent global environmental standards, companies are already turning towards waterless cleaning systems, recyclable materials as well as energy efficient methods.

Automation and AI

New generation HDI PCB fabrication is being transformed by automation and AI-powered solutions. From predictive quality control to automated material handling, these technologies serve in a competent manner for scale production improving efficiency, cost and product reliability at the same time.

FAQs about HDI PCB Manufacturers

What is the role of HDI PCB manufacturers in the electronics industry?

HDI PCB manufacturers make high-density boards with microvias, fine line widths, and advanced materials. Their products enable compact designs, faster signal transmission, and improved performance, making them essential for modern electronics.

Why is miniaturization important in HDI PCB manufacturing?

Miniaturization allows for smaller devices with higher performance capabilities. By shrinking line widths and increasing layer counts, HDI PCB manufacturers enable more compact and efficient designs, meeting the demands of industries such as consumer electronics and automotive.

What are the key challenges faced by HDI PCB manufacturers in 2024?

Challenges include meeting the demand for higher integration density, managing costs associated with advanced materials, and ensuring environmental sustainability. Rapid technological advancements and supply chain disruptions also pose challenges for the industry.

How do HDI PCB manufacturers ensure product quality?

Quality is ensured through rigorous testing and inspection, including optical measurements, electrical conductivity tests, and automated defect detection systems. Advanced tools such as X-ray imaging and laser scanning are commonly used to verify dimensional accuracy and reliability.

Which industries benefit most from HDI PCB manufacturers?

Industries such as telecommunications, automotive, healthcare, and consumer electronics benefit significantly from HDI PCB manufacturers. Their products enable high-performance applications in these sectors, supporting technological advancements worldwide.

Conclusion

HDI PCB manufacturers lead in innovation to enhance miniaturization, high-frequency operation and sustainability. The best manufacturers of HDI PCB boards in 2024 provides services for industries around the world, offering good quality circuits that allow the creation of new electronic devices. With a better understanding of what these manufacturers have to offer and how they can be leveraged, businesses can make more informed decisions and remain competitive in the market.

- 1Understanding UL 94V-0 Flammability Rating for Printed Circuit Boards (PCBs)

- 2HDI PCB Market Outlook 2025: Future Prospects, Growth Analysis & Innovations

- 3HDI PCB Design Comprehensive Guide: Mastering High Density Interconnect Technology in 2025

- 4Top 10 Flexible PCB Factories in 2025

- 5Top HDI PCB Manufacturers (2024)

- 6PCB core raw material CCL

- 7IC Substrate | Comprehensive Guide (2021)

- 8How to Make mSAP PCB?

- 9Top 10 IC Substrate Fabricators (2024)

- 10The Impact of Trump's Tariff Policy on Chinese PCB Industry and Countermeasures

- Skype ID: shawnwang2006

- Phone No。: +86-755-23724206

- Email: sales@efpcb.com

- Quick Contact