-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

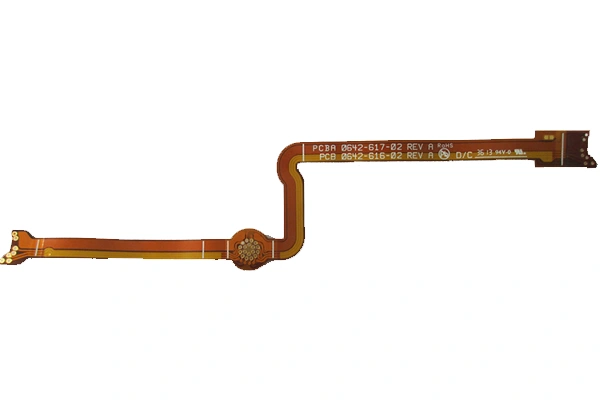

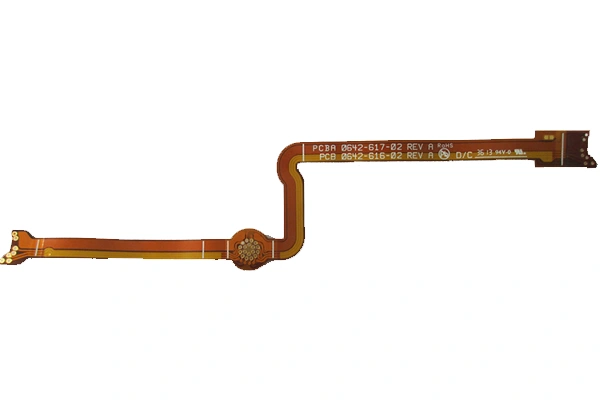

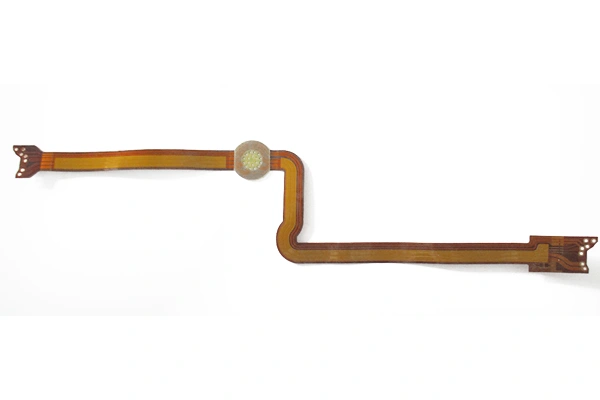

Part No.: E0215060179A

Layer count: 2 layer flexible PCB

Material: FR4, 0.15mm,0.5 OZ for all layer

Minimum trace: 2.8 mil

Minimum space: 2.5 mil

Minimum hole: 0.15mm

Surface finished: immersion gold

Panel size: 198*18mm/1up

Characteristics: Flexible, Dupond 3mil Polymide, immersion gold, FR4 stiffener, silver shield.

Flex PCBs, also referred to as flex circuits, provide a revolutionary way to design PCBs that can be bent, folded and wrapped around two-dimensional and three-dimensional shapes without affecting the electrical performance. These PCBs have found critical applications in the aerospace, automotive, medical device, consumer electronics, and telecommunications industries where space-constrained, lightweight and robust solutions are a must. As your reliable Flex PCB manufacturer for IPC Class III, we provide the highest quality flex circuits available for the most demanding applications as your trusted flexible PCB manufacturer. In this article, we will discuss how flexible PCBs are manufactured and what features make us different.

Flexible PCBs are made of flexible material such as polyimide or polyester film instead of rigid material so that the board can be bent and even twisted while still maintain the electrical connection.* In contrast to rigid PCBs, flexible PCBs provide more design flexibility and are lighter and more reliable in applications that require dynamic or static bending.

Our Expertise as a Sophisticated Flex PCB Manufacturer is Recognized by doing Defense Designs to IPC Class III You can be assured of Quality data for Design, Fabrication and Testing to ensure that your High Reliability, Aerospace, Military and Medical applications will meet or exceed your requirements. Advantages of Flexible PCBs

Flexible PCBs have alternative advantages & some reasons that can be good for hold them while designing your electronic product. Here are some of them:

Flexibility: Enables the PCB to be bent, folded, or twisted to fit in tight spaces or on moving objects.

Low Profile: Much thinner than rigid circuit counterparts which make them an excellent choice for space constrained or portable and wearable applications.

Reliability: The inherent reduced number of interconnects and solder joints means flexible PCBs are more durable and less prone to failure.

Thermal and Electrical Properties: Polyimide substrates exhibit good thermal stability and electrical insulate properties.

Save Space: Allows for smaller form factors due to the elimination of large connectors and cables.

Being a flexible PCB manufacturer dedicated to the IPC Class III standards, we have the confidence that each and every PCB we produce will have exceptional performance and reliability, even if they are exposed to the most extreme conditions.

Flexible PCBs must be produced using special processes and equipment if they are to be high-quality, durable, and in accordance with RPC Class III standards. Here elsewhere are the main procedures to produce successful kernels.

Design and Simulation

To create the PCB layout, the production begins. Flex PCB layouts will need to take a few additional factors into consideration including the bend radius, trace routing and impedance control. Our engineering team uses sophisticated design software to develop layouts that make the best use of space and reduce signal interference. By simulating the PCB’s operation in a real application, we are able to catch potential problems that can be fixed early in the design cycle.

Material Preparation and Selection

Selecting the right material is imperative for flexible PCBs. Polyimide is the most widely adopted substrate owing to its flexibility, thermal stability and electrical insulation properties. As one of the best flexible PCB manufacturer, we buy the best quality polyimide films and other materials which are consist with IPC class III. After the materials are chosen, they are meticulously prepared for processing.

Circuit Pattern Printing

The circuit pattern is printed on the flexible substrate through a high technique such as photolithography. The method includes covering the substrate with a photosensitive layer, exposing it to UV light with a mask, and developing the pattern. To meet IPC Class III requirements. Tight control over the trace width, spacing and alignment is required to achieve the performance and reliability needed.

Etching

Etching is the removal of unwanted copper to form the circuit traces. For flex PCBs, this step has to be done with maximum precision, because the material is fragile and bending/warping are easy to occur. The pattern of circuits are printed with precision using chemical etching in our environment.

Lamination

Multilayer flexible PCBs need to be laminated together to bond the layers. At this stage heat and pressure are used to bake the layers together so the borosilicate glass and around the copper will line up perfectly. As a flexible PCB manufacturer with expertise in IPC Class III, we adopt latest lamination technology to keep the flexibility of the material and to ensure interlayer connection reliability.

Drilling and Via Formation

Drilling and vias formation is necessary when drilling through different layer of the PCB. Laser drilling is commonly utilized to produce microvias and through-holes with extreme accuracy for flexible PCBs. This allows for continuity without introducing signal loss and interference.

Surface Finishing

Surface finishing is very important to protect the PCB to make sure the soldering during component assembly is reliable. Common Flexible PCBs finishes include ENIG (Electroless Nickel Immersion Gold), immersion silver and OSP (Organic Solderability Preservative). These coatings improve durability and are compatible with more advanced assembly methods.

Quality Testing

Every flexible PCB which we supply is subjected to stringent quality control to meet with (IPC Class III). This will involve electrical testing, thermal modeling, mechanical stress analysis. As a quality-oriented flexible PCB manufacturer, we promise that all our products are reliable and can be used directly in your application. Why Should You Choose Us as Your Flexible PCB Maker? Our company excels in the industry with our expertise, advanced technology and commitment to high quality flexible PCB production.

Why Our Customers Choose High Quality PCB for Their Flexible PCBs?

High quality and reliability competitive prices and terms excellent customer services. Trust booking advantages in-house design & manufacturing personal service professional sales staff multilingual assistance IPC Class III Compliance. We Withstand the most rigorous test industry standards and our products fulfill the highest levels needed for critical applications.

Custom Solutions: Close collaboration with clients through the entire process of design and manufacture of the flex PCBs general solutions for all the relevant industrial areas.

What are the benefits of flexible PCBs? Why use flexible PCB?

FPCs have multiple benefits such as light weight, saving in space, and improved reliability. Since they can be bent and shaped like ordinary wire, flexible printed circuit boards are well suited to compact and highly dynamic applications.

What are the components of flexible PCBs?

Flexible PCBs are usually manufactured using polyimide or polyester films as substrate. These substances exhibit superb flexibility, thermal resistance, high electrical insulation and electrical properties.

Do you produce high quality FPC for the medical industry?

Yes - We are a recognized provider of IPC Class III flexible PCBs and have the capabilities to produce your flexible circuit using high complexity designs - Contact us today to discuss your unique requirements and begin the conversation about the high quality flexible circuit you need.

What are the applications of flexible PCB?

Flexible PCBs have a broad range of application; such as aerospace, automotive, medical instrument, consumer electronics and telecommunication.

Are Flexible PCB High Temperature Capable?

Flexible PCBs constructed with polyimide substrates can withstand high temperatures and thus can be used in applications where they would be exposed to extreme heat. What Surface Finishes Are Suitable for Flexible PCBs? We can provide different surface finishes such as ENIG, immersion silver and OSP, to meet your different application needs.

How to control quality of flexible PCB?

We test every flex PCB we give each one of our customers to make sure they meet the IPC Class III standard. This essentially entails electrical testing, thermal evaluation, and mechanical stress analysis.

Is it possible to customize flexible PCBs?

Yes, we do offer customized solutions for specific needs of our clients. Our team collaborates closely with customers to develop and produce customized flexible PCBs.

What is the standard delivery time for flex PCBs?

Our efficient production process enables us to supply printed flexible PCBs in a timely manner without sacrificing quality. Turnaround times are dependent on the design complexity.

Why should I buy from you as my flexible PCB manufacturer?

With expertise, technologies and a relentless focus on quality, we deliver flexible PCBs that can satisfy even the most exigent needs. Our dedication to IPC Class III enables you to depend on critical performance.

Specialized expertise, state-of-the-art equipment, and rigorous quality standards are all involved in the production of flexible PCBs. As a top flex PCB manufacturer, we bring together creativity, knowledge, and innovative technologies to develop solutions that conform to IPC Class III.

Need custom designs? Fast production? Expert support? High Quality PCB is here. Contact us today to find out more about how we can assist with your flexible PCB requirements.