Burn in Board (BiB) Manufacturing Technology

The burn-in board (BiB) is also a critical element in the semiconductor industry that allows ICs to be tested under extreme environments for a long time to ensure that end products will perform reliably and have high durability. As the demand for good quality electronic devices is increasing day by day, BiB manufacturers are instrumental in providing advanced solutions to meet the rigorous requirements of the industry. The following however will help you understand some of the complexities of burn-in board manufacturing technology and differentiate the core products of one of the leading BiB manufacturers.

The Importance of a Burn-in Board for the Semiconductor Application

Burn-in boards stress ICs at high temperature, voltage, and current for a prolonged time. This process, called burn-in testing, is important to identify early failure and to verify the reliability of devices prior to using them in critical applications. EngineeringTo attain the level of quality needed for high thermal load and electrical load applications, BiB manufacturers must follow stringent engineering specifications.

Today's burn-in board BiB technology is world-class and innovative by industry standards, utilizing state-of-the art materials, design and manufacturing best practices and methods. These have allowed BiB manufacturers to deliver higher efficiency, higher robustness and flexibility in meeting different customer requirements. Features of Advanced Burn-in Boards

The difference in the output and performance of a high quality BiB manufacturer's products. The following are some of the characteristics of the high-end burn-in boards:

1. Customizable Designs

Top BiB providers provide highly configurable products according to IC type and testing requirements. Burn-in boards are designed with different pin configurations, voltage requirements, and thermal profiles for memory chips, microprocessors, power devices, among others. This flexibility guarantees best testing environment and result accuracy.

2. High-Temperature Resistance

Burn-in boards are exposed to severe thermal conditions in the process. Polyimide substrates and high-tech laminates are used by manufacturers in production that will resist these environments. These substances have outstanding thermal properties, which help maintain the integrity of the board even after a long period of application.

3. Superior Electrical Performance

High importance placed on electrical reliability in testing Burn-in Testing reliability of the electrical system is of utmost importance in the testing procedures such as burn-in testing. BiB producers utilize cutting edge circuit designs and precision routing techniques to reduce signal loss, interference and power noise on their boards and networks. This leads to repeatable and accurate execution results, which is important to detect a faulty instrument.

4. Durability and Longevity

A robust burn in board is required to meet the needs of immersion in high strain fields regularly. The board manufacturers BiB are eternal in life with strong connectors, wear-resistance finishes, reinforced solder joints and so forth, which means they greatly extend the life of their boards, help customers reduce the replacement frequency and save more in the long term.

5. Scalability and Efficiency

With the growth of semiconductor production, burn-in boards will be expected to hold more ICs, while maintaining an acceptable performance level. A leading BiB supplier uses novel designs that take advantage of the board space, heat dissipation and throughput by allowing for faster and more efficient testing.

Advances in Burn-in Board Fabrication

The top BiB manufacturers spend a lot on research and development to maintain their competitiveness. Upgrades in burn-in board fabrication include:

- Automated Lines of Production: Production lines are automated, assuring precision and uniformity in all processes including material handling, process soldering, device assembly.

- Sophisticated Thermal Simulation Tools: These simulations enable the production of boards that are specifically designed to manage heat, making sure stress is equally applied to all ICs.

- Sustainable Practices: Green BiB producers are committed to the use of sustainable practices and materials, with an emphasis on minimizing waste and energy use without compromising high quality products.

- The technology: Best Practice BiB Why Choose a Leading BiB Manufacturer From the excellent biB manufacturers to the lower standard producers, customers should be able to identify good performance and reliability results.

Why Choose a Leading BiB Manufacturer Selecting the right BiB manufacturer is critical to obtaining consistent semiconductor test results. Expertise in technology and the latest production facilities run by High Quality PCB, the trusted manufacturer that can provide ISO9001 quality assurance, our burn-in board will meet the highest standard of industry. The capacity to gear customizable solutions to latest semiconductor technology evolving and durability focus will guarantee that their customers received evolving capable products for latest semiconductor testing.

Summary

Burn-in board fabricating technology can be said as a mother technology of semiconductor industry for the semiconductor product, which estimate the reliability and quality of electronic device. Advanced burn-in boards developed and manufactured by the world’s leading BiB manufacturers, delivering ever higher performance for all testing needs. Investing in innovative technologies and sustainable approaches, BiB manufacturers are continuously advancing in semiconductor testing to enable design high-performance devices for the growing market.

Look for BiB manufacturers that have a proven track record, technical knowledge and are continually bringing innovative solutions to the table that will allow you get the best from your burn-in board in terms of performance, reliability and efficiency. Their products have also ensured the reliability of ICs and therefore have contributed to the technologies of semiconductors as a whole.

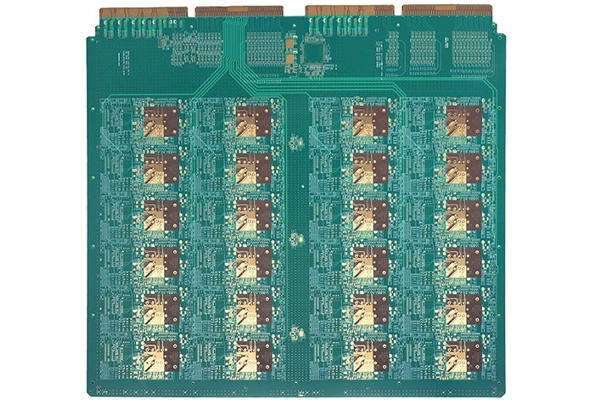

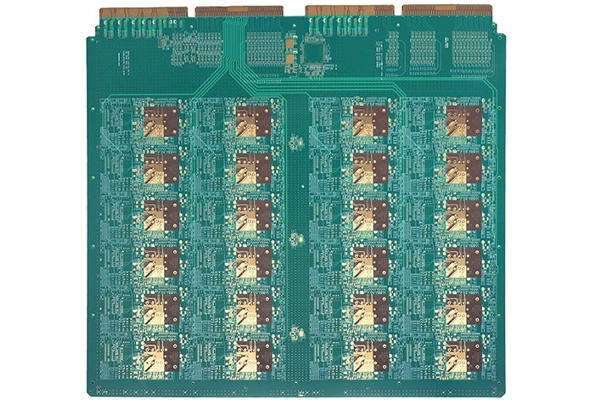

Birn in Board (BIB)