-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

Immersion gold PCB, 94 V0 PCB

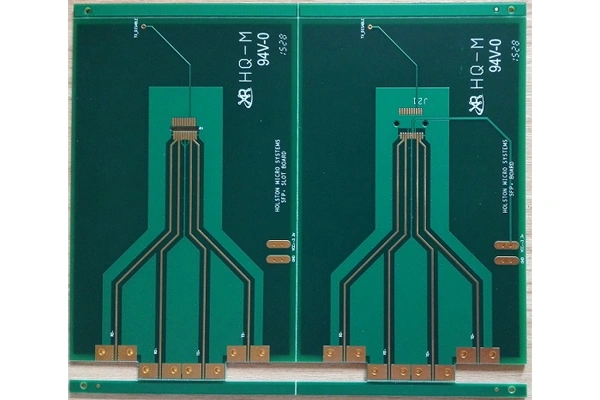

Part No.: E0215060179A

Layer count:2 layer

Material: FR4, 1.0mm,0.5 OZ for all layer

Minimum tack:5 mil

Minimum space: 5 mil

Minimum hole: 0.30mm

Surface finished: immersion gold

Panel size: 258*238mm/2up

Characteristics: FR4, high TG, immersion gold, impedance control

In businesses where safety, uptime, and compliance with regulations are the only options, the flame-retardant behavior of printed circuit boards is a critical pillar of product quality and assurance. Our 94 V-0 PCB design and engineering process combines stringent UL standards with precision manufacturing to provide predictable quality at scale. Here is a concise summary to give you an idea of how our methods, materials and tests translate into concrete benefits for OEM and system integrators looking for a dependable board.

The 94 V-0 rating means a material can stop burning quickly after being ignited and does not drip flaming particles. In industrial controls, automotive modules, medical devices and telecom infrastructure applications, this is critical to reducing risk and protecting equipment. Selecting a reputable 94 V-0 PCB manufacturer ensures that your materials and stack up conform to the UL sourcing requirements without compromising your electrical performance or mechanical definition.

Superior flame retardant performance should be accompanied with stable electrical performance. We select materials with high glass transition temperature, low dielectric loss and well-behaved coefficient of thermal expansion for tight impedance control and long term reliability.

Consistent resin system FR-4 types that are proven 94 V-0 high-TG to minimize crippling under lead free processing. High-TG options to minimize warpage for lead-free assembly environments. Please Note: These documents are available electronically only low-DF laminates for RF/high-speed digital Layers. Controlled CTE matching between copper and dielectric to protect vias

By combining innovative resin systems with matched prepreg, the 94 V-0 PCB supplier ensures predictable and consistent stack up performance over intricate designs.

Signal fidelity depends on geometry, materials, and process control. We design impedance profiles, reference planes and return paths for good transitions and solid EMC, heat management to keep parts in safe operating windows. Conductor patterning designed for impedance stability and crosstalk noise minimization

Gradients in copper thickness adjusted to current density and heat dissipation rates. Embedded thermal vias and heatsink interfaces for dissipating hot spots. Techniques for shielding power noisy and mixed-signal areas

This combination of electrical and thermal design performance enables the 94 V-0 PCB supplier to deliver dense packaging solutions without sacrificing reliability.

Reliability begins on the floor. Our processes are designed to minimize variation, keep traceability, and build to the lion’s share of customer specific needs.

Laser and mechanical drilling (strict tolerance of position)

High-reliability via formation (stacked microvias with resin)

Controlled lamination cycles to avoid void formation and resin recession

Cleanroom plating lines produce even copper deposition on your substrate and generate sturdy, reliable interconnects.

Surface treatments such as ENIG, ENEPIG, and Immersion Silver are selected based on application requirements.

Each process is SPC-controlled and traceable at the lot-level which allows the 94 V-0 PCB supplier to validate compliance and helps reduce audit finding.

Trusted Quality Assurance and Regulatory Compliance to Your Satisfaction

Quality is reported, not assumed. Our validation scheme combines in-process and final functional testing to ensure that each and every board meets spec. UL 94 testing and the routine surveillance audits to maintain material uniformity

IPC Class 2 and Class 3 including AOI, X-ray, and micro sect analysis

Solderability assessment adapted to lead-free windows for sustainable assembly yields

Adherence to these controls helps differentiate the 94 V-0 PCB manufacturer in markets where there is no room for failure.

Bass 94 V-0 PCB DFM Collaboration for Faster and More Reliable Builds

Good manufacture starts with good design. We work together from the beginning to optimize routing, via strategies, and thermal solutions, which reduces cycle time and enhances assembly quality. Impedance and stackup feasibility check constraints review.

Reduce warpage and improve planarity with these copper balancing techniques

Panelization techniques to maximize yield and minimize stress points

Simple accept-context criteria which help extent of test relate to risk

As a result, the 94 V-0 PCB manufacturer is able to minimize the number of redesign loops and realize a faster time to market.

From facility management, to aerospace, to instrumentation, flame retardant boards provide stability, assurance, and reliability. Industrial automation drives and safety relays

Automotive power distribution and ADAS modules

Medical diagnostics and patient monitoring systems

Telecom baseband, power modules, and network infrastructure

Consumer appliances requiring enhanced safety margins

An experienced 94 V-0 PCB manufacturer knows that your design must be able to handle real-world stress while still passing regulatory testing.

Reliable delivery counts, not just engineering beyond engineering, dependable delivery matters. Our integrated supply chain and capacity plan enable us to keep programs on track.

Dual sourcing for critical multi-lamination to minimize risk

Forecast-driven inventory for consistent lead times

Flexible lot sizes from prototyping to mass production

Worldwide logistics support with customs-ready documentation

These allow for consistency throughout the pilot and full production runs for the 94 V-0 PCB maker.

Our value is in combining robust compliance with practical manufacturability. Whether the stackup modeling, thermal analysis, controlled lamination or end-of-line verification, all decisions are made with performance and safety in mind. If you need your roadmap to include high-reliability boards with established flame-retardant performance, an experienced 94 V-0 PCB manufacturer possesses the process maturity, testing depth, and partnering DFM support to bring your designs to production confidently. The bottom line is this: engineering with safety-class materials requires a like level of discipline in engineering and process control. With that foundation, 94 V-0 board not only provide compliance, but they also support long term electrical stability, higher assembly yields, and minimized potential headaches in the field – just what mission critical products need.