-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

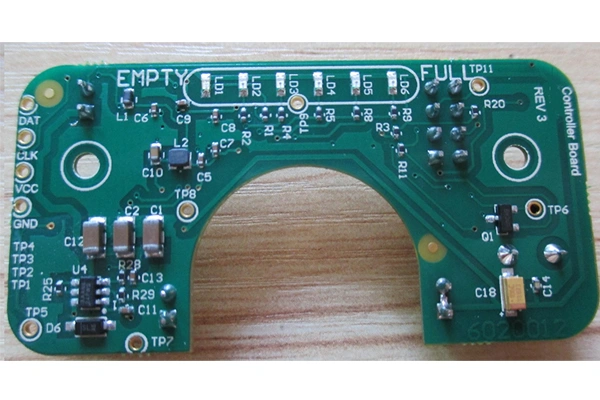

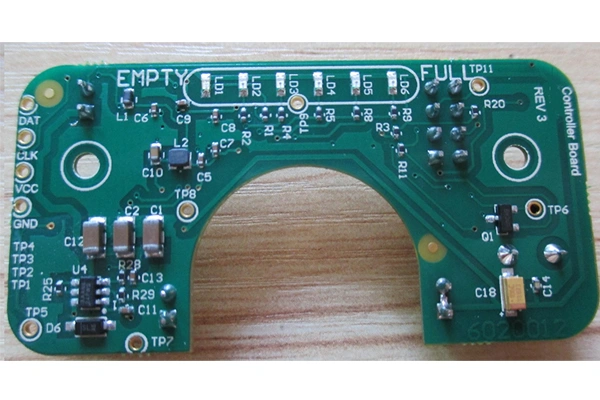

Name: PCB Assembly, circuits board Assembly for medical device

Part No.: E0215060190A

Layer count: 2 layer

Material: FR4, 1.6mm, 1 OZ for all layer

Minimum tack: 5 mil

Minimum space(gap): 5 mil

Minimum hole: 0.20mm

Surface finished: ENIG

Panel size: 58*118mm/1up

Application: Medical devices.

Characteristics: multilayer, min packing 0603, Lead free assembly, ROHS compliant

Printed circuit board assembly is extremely important in the medical device market where accuracy, reliability, and compliance are required. With the increasing demand for advanced medical technology, manufacturers will have to embrace advanced methodologies to guarantee the performance and safety of the products. This article will investigate the essential elements of medical device PCB assembly, and what makes high quality assemblies different.

Medical device PCBA is subject to the strictest standards such as ISO 13485, IPC Class III, It guarantees reliability for life-critical applications. They are applicable to the high stress environment of the lungs, heart, and brain and the challenges on body as being exposed to the elements.

Selecting the right materials is among the most critical considerations in assembling PCBs for medical devices. Premium raw materials to achieve high durability and thermal stability, quality substrates such as FR4 or specialized ceramics are employed. Also, parts must be procured from reputable vendors to ensure that they would be reliable for a long time.

Then there is the issue of high precision production. Sophisticated equipment processes, such as surface mount technology (SMT) and automated optical inspection (AOI) help guarantee the components are placed correctly, reducing the potential for defects. When it comes to medical devices, a small mistake during PCB assembly can render the device unusable or unsafe.

High Quality PCB is a specialized manufacturer of medical device PCB assembly, the quality and reliability that your application demands. Following are the features that make our products stand out from the rest.

Conformance to Industry Standards: Our treatments meet or exceed ISO13485 and IPC Class III execution requirements for high quality control. This guarantees enhanced performance in the most challenging applications.

Working with a manufacturer that has expertise in medical device PCB assembly can provide substantial benefits. The global medical electronics market is anticipated to register a CAGR of 7.9% through 2030, as per a study by Grand View Research. This growth emphasizes the need to rely on experts who can navigate the complexities of med device manufacturing.

A specialized partner will have knowledge in compliance, leading edge technologies, and custom solutions to you can rest assured that your devices will be able to pass regulatory protocols and perform well. From diagnostic devices to systems that support life, precision PCB assemblies are the foundation of dependable medical devices.

The assembly of a medical device PCB is a vital stage, requiring accuracy, trustworthiness and adherence to rules. By recognizing the particular needs of the industry and partnering with a reliable manufacturer, organizations can rest assured that their products are of the highest quality. This guide lays the groundwork to enable success for PCB assembly in the medical industry - Whether you develop diagnostic tools, wearable technology, or surgical instruments.

If you are seeking a trusted name for medical device PCB assembly, we can deliver expertise and quality that will help you stay a step ahead in this fast paced industry.