-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

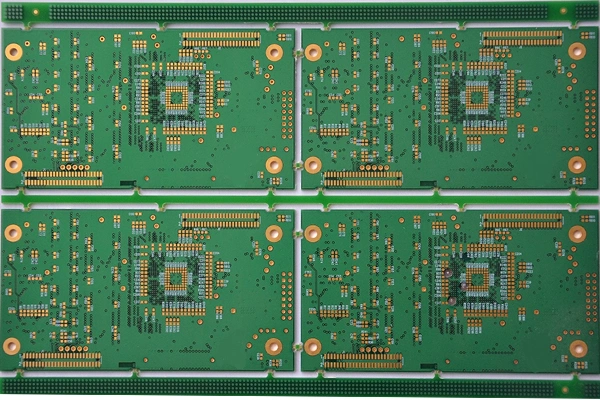

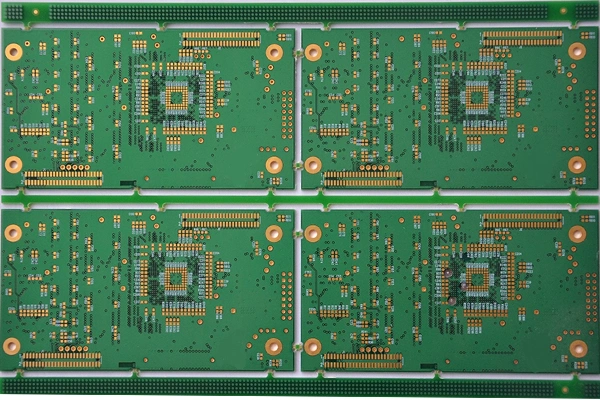

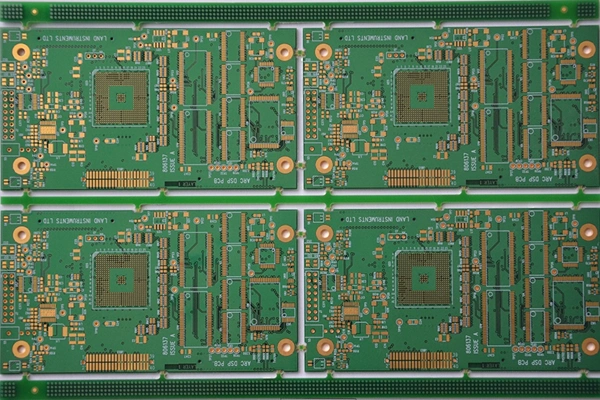

Part No.: E1015060179A

Layer count:10 layer

Material: FR4 TG180, 1.6mm,0.5 OZ for all layer

Minimum tack: 3.5 mil

Minimum space: 3.5 mil

Minimum hole: 0.20mm

Surface finished: ENIG

Panel size: 238*358mm/4up

Characteristics: High TG, impedance control, immersion gold( AU>2 microinches), BGA.

In the field of high precision electronics, you need to have the skills of an immersion gold PCB manufacturer to provide top quality PCBs that can be applied to high demand areas. Immersion gold PCBs are known for high quality surface finish, good solderability and excellent electrical performance. As a qualified immersion gold PCB manufacturer, our company leads the market in innovation, utilizing precision engineering and advanced technology to design PCBs that deliver not only superior functionality, but also outstanding durability.

The immersion gold technique, or ENIG (Electroless Nickel Immersion Gold), is the surface treatment technology accepted by best Immersion Gold PCB Manufacturers in the world. It is a two processes where first a layer of nickel is deposited on the copper then a layer of gold. The nickel also acts as a barrier to copper migration and the gold is a great conductor and shields the nickel from oxidization.

The process of production of our immersion gold PCB is rigorously monitored to bring about consistent thickness and adhesion. We employ state-of-the-art chemical baths and automated plating lines to maintain consistency in production on high volume production orders. It is this attention to detail that makes our company the preferred supplier for immersion gold PCB in the high reliability sector.

Being dedicated manufacturer for immersion gold PCB, our products bring you a lot of benefits as follows:

Outstanding Flatness of Surface: The common cause of missing balls within BGA (ball grid array) assemblies is uneven surfaces and the immersion gold finishes over a planar surface making it much safer to use for fine pitch components and BGA assemblies.

Higher Solderability: Our PCBs have excellent solderability, which lowers the chance of defects during assembly and increases total yield.

Corrosion Resistant: The gold layer protects the PCB against environmental impact, making the PCB last longer.

Low Contact Resistance: Immersion gold plating is also known for low contact resistance, which is beneficial for signal integrity and performance in high-speed circuitry.

RoHS Compliance: All our immersion gold PCB are produced under the rigorous environmental standards to be free of any harmful substances.

Therefore, the customizable products are mainly utilized in telecommunications, medical devices, automotive electronics and consumer electronics. As an immersion gold PCB manufacturer, not only do we know what matters in reliability and performance, but our products have a proven track record of exceeding industry standards. Capacities of Advanced Manufacturing

Our gold platted PCB factory has the most advanced equipment and quality control. Professional engineers participate in all stages of production from design validation to end inspection and striving for excellence.

Precision Imaging and Etching: We employ high-resolution imaging with controlled depth etching to produce minimal undercut and over etching.

Electroplating Lines Automation: Immersion gold PCB manufacturer production lines are automated resulting in a consistent gold and nickel thickness for each board according to the designing specifications.

Strong Quality Control: Each PCB is subject to rigorous testing which includes electrical testing, surface examination, and screen of environmental stress.

With this infrastructure in place we are able to meet complicated design requirements and provide immersion gold PCBs with quick turnover.

Al many good immersion gold PCB manufacturing know us truly ' one size no fit all'.

Our engineering team collaborates directly with clients to develop customized solutions.

Multilayer boards, HDI PCBs, controlled impedance or special materials? Our professionals provide expert advice from the prototype to the volume manufacturing. Besides customization, we also provide full technical support, from design layout and material selection to process troubleshooting. Our dedication to customer satisfaction is evident through our attentive service and active communication.

Sustainability Commitment

For our immersion gold PCB manufacturer process, sustainability is the core value. We apply green solution in the packaging and waste separation in handling waste, water recycle in production, and addiction use of environment friendly chemical within our production procedure. Our facility meets international environmental standards, reflecting our commitment to sustainable manufacturing.

So if you want to ensure the performance and reliability of your electronic products, It's essential to select the best immersion gold PCB manufacturer. Our business leverages knowledge, state-of-the-art technology and tireless dedication to quality to create PCBs that hash out the best results. With proven success across a broad range of industries, you can trust us to be your partner in immersion gold PCB solutions that help you lead innovation and success.

Get in touch with us today and learn how our Immersion Gold PCBs manufacturing services can take your next project to the next level. Discover the impact that accuracy, dependability, and commitment to customers can have — invest in a top immersion gold PCB producer for your business needs.