-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

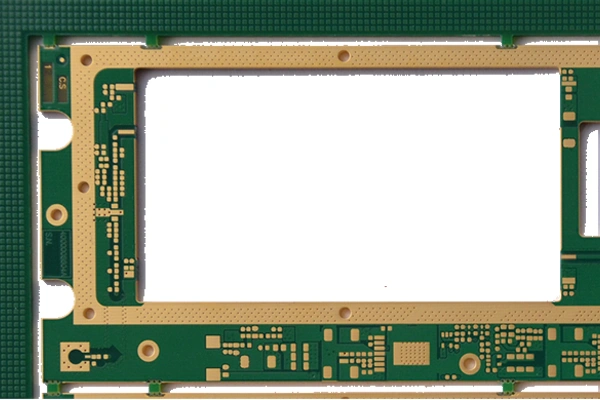

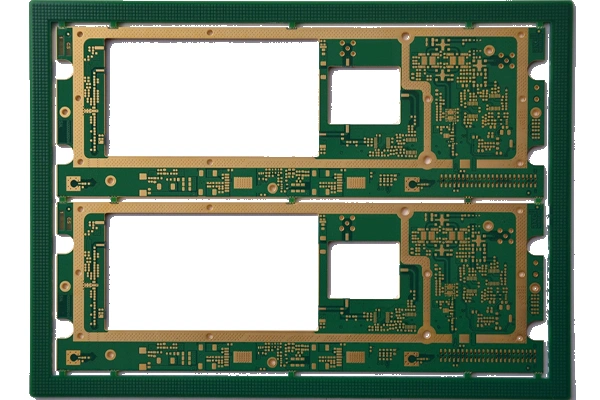

Part No.: E0415060179A

Layer count: 4 layer

Material: FR4, 1.6mm, 1 OZ for all layer

Minimum tack: 6 mil

Minimum space: 6 mil

Minimum hole: 0.25mm

Surface finished: ENIG

Panel size: 238*158mm/2up

Characteristics: High TG, impedance control, immersion gold( AU>2 micrometers), edge plating.

In the expanding electronics industry, immersion gold PCB manufacturer plays an important role in high performance PCB. Immersion gold PCBs have a high quality surface finish, reliability and good solderability, which makes them suitable for precision and high endurance applications. As a professional immersion gold PCB manufacturer, we have rich experience in producing high quality and high performance PCB.

The type of components you are using on your PCB itself dictates the surface treatment method, such as immersion gold, or ENIG (Electroless Nickel Immersion Gold) which is a high-end surface treatment that consists of depositing a layer of nickel followed by a thin layer of gold. This processing method provides good conductivity, solderability and oxidation protection.

When it comes to our immersion gold PCB production process, we spare no detail to maximize uniformity and precision. We use high-tech chemicals baths and automated plating processes to provide uniformity and maximum adhesion. This level of accuracy is what makes us as the best immersion gold PCB manufacturer in the industry.

Being the best board manufacturer from immersion gold PCB, our products are trusted by thousands of high-tech engineers for their outstanding performance and reliability. These are the main advantages of our know-how in immersion gold PCBs:

Our impregnation gold PCB manufacturer has advanced equipment and perfect quality inspection system. From design validation to final test, every step of the manufacturing process is overseen by veteran engineers passionate about quality.

With this, we are able to meet high demands on designs and short delivery time for immersion gold PCBs.

Being a professional immersion gold PCB manufacturer we know each project is different. Our engineers work with customers to create custom solutions that meet the unique requirements of their applications. From prototype to volume, our technical support team will help you through every step of the process if you need multi-layer boards, HDI designs or help with impedance control.

Even more than leading-edge, the technology is hand of customization supports you a lot technical so specializing in the technical also keeps you happy! We have full technical help to assist you in customization, suggestions on design work, advice on materials or with process or application questions.

The way we work with clients is a testament to our commitment to customer satisfaction.

In response to the Challenge: Commitment to Sustainability - making it real in a future leaning way

Our immersion gold PCB fabrication design services and manufacturing processes are based on the principles of environment-friendly sustainability. We practice green manufacturing at every phase of our production process, including waste minimization, water recycling, and employing non-hazardous substances. Our environmental management system certified to international standards, we value our promise of being an eco-friendly manufacturing facility.

It is essential to choose a good immersion gold PCB manufacturer to have good performance and reliability of your electronic products. We are expertise in advanced technology, best quality and highest reliability PCBs surpassing industry standards. We have demonstrated history of success for numerous industry solutions, and can be considered a go-to source for immersion gold PCB for your business needs.

Get in touch with us to see how our capabilities in the production of immersion gold PCBs can advance your next project. Discover the difference precision, reliability and customer focus can deliver—partner with a top immersion gold PCB manufacturer to meet your business requirements.