-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

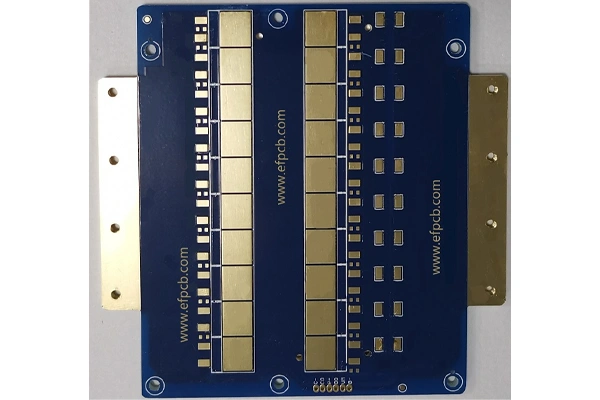

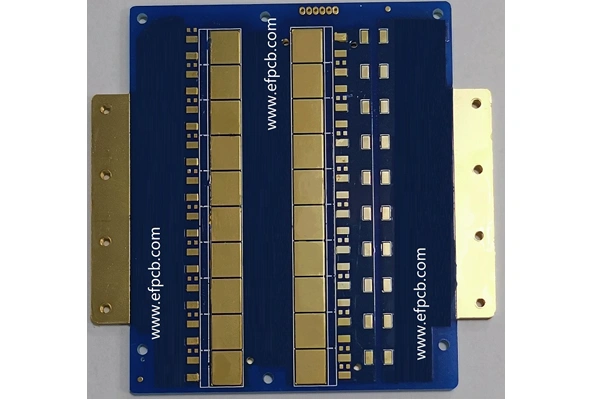

Part No.: E0217060129A

Layer count: 2 layer

Material: FR4 TG170 3 OZ+Copper Coin

Minimum trace: 18 mil

Minimum space(gap): 32 mil

Minimum hole: 0.60 mm

Surface finished: immersion gold

Panel size: 128*138mm/1up

Introduction to Embedded Copper Solutions in PCB Technology In modern electronics, embedded copper coin PCB technology has surfaced as a key answer to the challenges of heat dissipation and high-power applications. With more than 15 years of manufacturing embedded copper coin PCB products, we lead the industry in achieving breakthrough performance enhancements for your applications. In this article we go to heart of this technology from feature set to benefits and to manufacturing aspect.

Embedded copper coin PCB technology involves using a copper coin rather than a copper fin or wire to be embedded on both sides of a PCB, which can greatly improve heat dissipation in electronic devices. This is particularly important in such high-power-component-heat-generating-fields, like LED lighting, automotive electronics, power modules, industrial appliances etc. The copper coins are embedded directly into the PCB enabling the heat from the components to be efficiently removed, helping to ensure the stable operation of the device for longer.

For the embedded copper coin PCB automotive industry, we have developed advanced techniques. What distinguishes us from our competitors is the fact that our PCBs are designed and manufactured not only to the highest quality standards and with the best materials, but also to deliver the best thermal and mechanical stability.

Structural details working principle Solution in with the lowest cost and highest quality. Benefits for Thermal Conductivity. One of the key benefits of embedded copper coin PCBs is its superior heat dissipation. The copper token serves as a thermal bridge, pulling heat away from sensitive elements and keeping them cool. This means they can be used in applications where the conventional methods of managing thermal, including heat sinks or thermal pads, just do not cut it.

Embedded copper coin PCBs can support high currents and power loads while maintaining excellent performance. The presence of copper coins improves the thermal resistance of the board and also allows us to avoid problems like board delamination or overheating. This is why they are a favored option for power electronics and other devices that are high-power in nature.

Flexible Design Options

As a leading manufacturer of embedded copper coin PCB, we provide best customized solutions to meet your requirement. From the dimensions and shape of the copper coin to the height of the PCB, all can be personalized for the best results in your application.

Stronger Mechanical Stability

The insertion of copper coins not only enhances thermal performances but also improves the mechanical stability of the PCB. This is especially crucial in applications subjected to harsh conditions or extreme mechanical load, e.g automotive or aerospace electronics.

The production of embedded copper coin PCBs requires special know-how. Our proprietary manufacturing process includes several key steps:

Selection of Design and Materials

It starts with a detailed design specific to the application. Premium materials with copper coin and PCB substrate to ensure longevity and performance.

Precision Milling

A pocket is milled into the PCB layer in order to place the copper coin. This stage demands high accuracy to obtain a perfect matching, since a tiny displacement can influence the thermal conductivity and mechanical stability of the board.

Copper Coin Embedding

The copper coin is embedded in the machined pocket for good contact and security. Sophisticated bonding techniques are applied to close any gaps between the copper coin and the pcb uncopied, and thereby, the maximum thermal transfer efficiency is attained.

Lamination and Finishing

The copper coin is embedded by the PCB lamination, which forms the protective layer. Other finishing processes, such as plating and solder masking, apply also is performed to make sure the board conforms to the industry standard.

Quality Testing

We make quality the priority in every aspect of the production process as a top embedded copper coin PCB manufacturer. The PCBs are tested to thermal, electrical, and mechanical specifications prior to shipment.

Our company prides itself on being an exceptional manufacturer for embedded copper coin PCB and we are your ideal choice. Through our years of experience in industry, we have developed advanced manufacturing processes which makes us capable to deliver products with superior performance and high reliability.

We know that every application is different, and that's why we collaborate with you on a solution that fits your unique needs. From prototyping to mass production, we are your single source for all of your embedded copper coin PCB requirements.

Embedded copper coin PCBs find their application in high thermal, and high power requirements industries. Typical use cases include:

LED lighting systems

Automotive electronics

Power modules and converters

Industrial control systems

Aerospace and defense electronics

By selecting a trusted embedded copper coin PCB manufacturer, you will have the assurance of your products being integrated with leading thermal management solutions, driving up its potential and life span of products.

The technology of embedded copper coin PCBs is transforming the design of high-power, high-heat applications. Given its excellent thermal conductivity, mechanical stability and customizable design options, this is poised to be the preferred solution for producers in a variety of fields.

As a professional embedded copper coin PCB manufacturer, we strive for excellence in R&D, production, sales and service. Contact us now to discover how we can take your products to the next level with our cutting-edge solutions.