How to Manufacture Impedance Control PCB: Precision Engineering for High-Speed Electronics

Understanding Impedance Control in Modern PCB Manufacturing

In today's rapidly evolving electronics landscape, signal integrity has become paramount for high-frequency applications. As an experienced impedance control PCB manufacturer, we recognize that achieving precise impedance values requires meticulous attention throughout the production process. The growing demand for faster data transmission rates in telecommunications, aerospace, and consumer electronics has elevated impedance control from a specialized requirement to an industry standard.

Impedance control refers to matching the characteristic impedance of transmission lines on printed circuit boards to specific values, typically ranging from 25 to 120 ohms. This precision ensures minimal signal reflection and distortion, critical factors when dealing with high-speed digital signals or radio frequency applications. Our manufacturing facility employs state-of-the-art equipment and rigorous quality control measures to deliver consistent impedance values within tight tolerances.

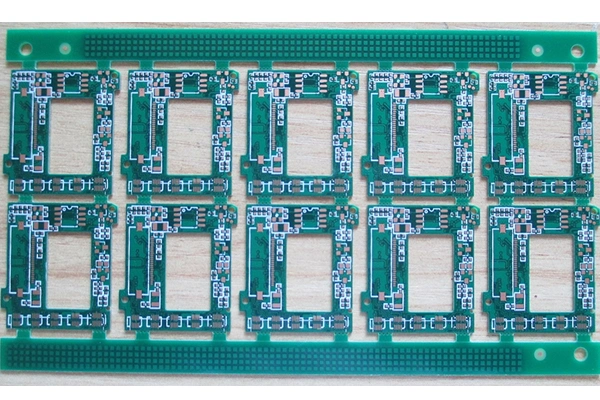

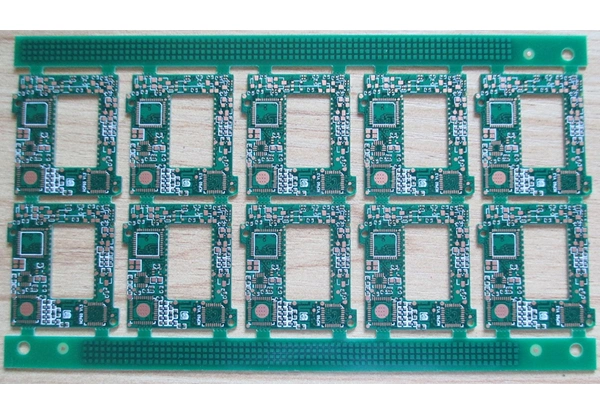

Advanced Materials Selection and Stack-up Design

The foundation of superior impedance control begins with material selection. Our engineering team carefully evaluates substrate materials based on their dielectric constant stability, loss tangent characteristics, and thickness uniformity. We primarily utilize high-performance materials such as Rogers, Shengyi, and Taconic laminates, which offer exceptional electrical properties and dimensional stability across temperature variations.

As a leading impedance control PCB manufacturer, we understand that stack-up design significantly influences impedance values. Our proprietary software tools calculate optimal trace widths, spacing, and dielectric thickness combinations to achieve target impedance specifications. We maintain comprehensive material databases, continuously updated with actual measured values rather than relying solely on nominal datasheet specifications. This approach ensures greater accuracy in impedance predictions and reduces the need for costly redesigns.

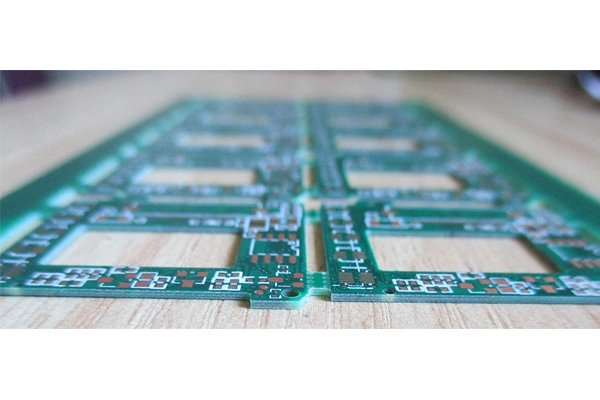

Precision Manufacturing Processes and Equipment

Manufacturing excellence demands investment in cutting-edge technology. Our production line features laser direct imaging systems that deliver exceptional registration accuracy and fine line resolution. These capabilities enable us to maintain trace width tolerances within ±10% for standard impedance control requirements and ±5% for critical applications.

The lamination process represents another crucial phase where our expertise as an impedance control PCB manufacturer truly shines. We employ vacuum-assisted lamination presses with precise temperature and pressure profiling capabilities. This technology ensures uniform dielectric thickness across the entire panel, eliminating variations that could compromise impedance consistency. Our technicians monitor resin flow patterns and adjust parameters to prevent thickness variations exceeding 0.05mm.

Comprehensive Testing and Quality Assurance

Quality assurance forms the backbone of our manufacturing philosophy. Every impedance control PCB undergoes rigorous testing using time domain reflectometry equipment capable of measuring impedance values with ±1% accuracy. We perform both coupon testing and actual trace measurements to verify compliance with customer specifications.

Our laboratory maintains ISO/IEC 17025 accreditation, demonstrating our commitment to measurement accuracy and traceability. As a trusted impedance control PCB manufacturer, we provide detailed test reports including impedance profiles, cross-sectional analysis, and statistical process control data. This transparency enables customers to validate our manufacturing capabilities and make informed decisions about their critical applications.

Continuous Innovation and Customer Support

The electronics industry never stands still, and neither do we. Our research and development team continuously explores emerging materials and processes to enhance impedance control capabilities. Recent innovations include implementing artificial intelligence algorithms for predictive impedance modeling and developing proprietary surface treatments that improve signal integrity at frequencies exceeding 40 GHz.

Customer collaboration remains central to our success as an impedance control PCB manufacturer. We offer comprehensive design review services, helping clients optimize their layouts for manufacturability while maintaining electrical performance objectives. Our engineers provide stack-up recommendations, conduct signal integrity simulations, and suggest design modifications that reduce production costs without compromising quality.

Manufacturing impedance control PCBs demands expertise, precision equipment, and unwavering commitment to quality. Through careful material selection, advanced manufacturing processes, and comprehensive testing protocols, we consistently deliver products that meet the most stringent impedance specifications. As technology continues advancing toward higher frequencies and faster data rates, partnering with an experienced impedance control PCB manufacturer becomes increasingly vital for project success.

Wearable device application