-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

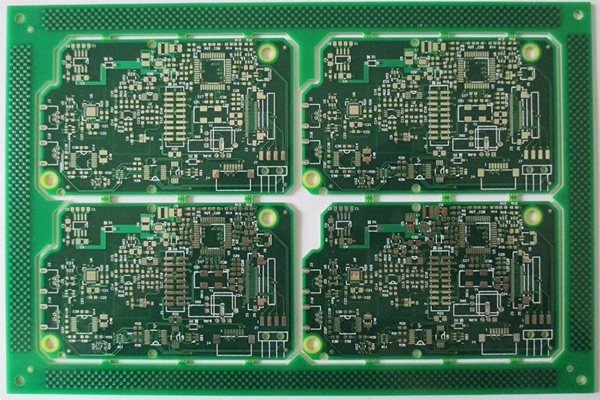

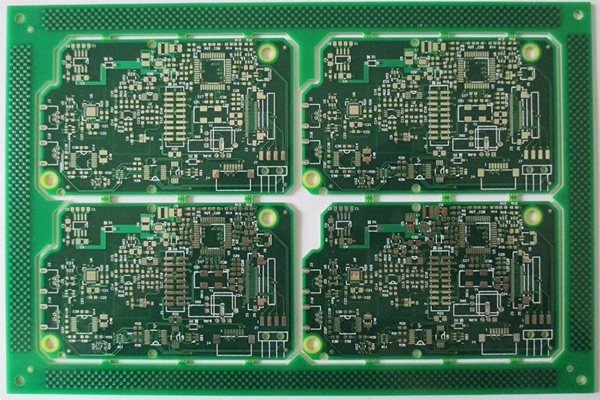

Part No.: E0615060789A

Layer count: 6 layer

Material: FR4, 1.6mm, 1 OZ for all layer

Minimum track: 4 mil

Minimum space: 4 mil

Minimum hole: 0.30mm

Surface finished: LF HASL

Panel size: 258*308mm/4up

High voltage PCBs are custom designed PCBs withstanding high voltages and high power in severe environments. CTI (Comparative Tracking Index) is an important rating that reflects the level of electrical tracking on the surface of the insulating material. High CTI means that the material can withstand a higher level of electrical arcing and breaking down the insulation material, so high CTI PCB can be applied to high safe and reliable demanded application. As a professional High CTI PCB manufacturer, we are capable to provide long life and high quality products for your special needs in automotive, industrial, power electronics and more industries.

CTI is an indicator to tell us a material can prevent electrical track or not, which is a phenomenon involving the flow of current on the surface of insulating materials caused by contaminants (like dust, humidity and chemicals). The CTI value is given in volts and can be divided into different classes where materials with a high CTI value mean generally greater than 600V. High CTI PCBs employs materials with strong insulation that lessens the possibility for short circuits, harm to the components or system malfunctions that is produced by electrical tracking. These PCBs are critical, especially in HV (high voltage) situations.

They have the following advantages which allow them to be a must have for critical application:

Increased Safety: Better insulated due to the high CTI value results in less chance of electrical arcing, which leads to safer system.

Robustness: Such PCBs are made for use in the vulnerable environment of moisture, dust, chemical, etc.

High Voltage Withstand: High CTI materials enable the PCB to be exposed to high voltage without affecting its performance.

Improved Reliability: They also deliver long-based reliability as they reduce the chance of electrical tracking in mission critical applications of high CTI PCBs. A high-quality manufacturer of High CTI PCBs with more than 15 years of experience in the OEM industry, we know how significant these are in quality assurance regimes and craft our designs to exceed industry accepted standards. How Are High CTI PCBs Manufactured? To make high CTI PCBs, high quality materials and precision process are required.

High CTI PCB Main Steps

Material selection

The insulating material is the platform of a high CTI PCB. High CTI value materials such as FR-4 or special composites are available to provide outstanding resistance to electrical tracking. We are a reputable manufacturer of High CTI PCBs and therefore we scrupulously choose high quality materials that are compatible with your application.

PCB Design and Layout

The design stage is essential for achieving good results. High CTI PCBs may also necessitate increased distance between conductive traces to avoid arcing, particularly at high voltages. Our engineers employ state of the art design software to develop layouts that optimize safety and productivity.

Laminating and Layering up

High CTI PCBs can be multilayer to support intricate layout. The lamination procedure has to be so executed as to the high CTI property of the material could be brought out in a sufficient bonding and lining up of the layers.

Drilling and Plating

Holes and vias are drilled with high precision. The plating process provides a consistent, durable electrical conductive layer while maintaining the insulating properties of the PCB.

Surface Finishing

Surface finishes such as HASL (Hot Air Solder Leveling), ENIG (Electroless Nickel Immersion Gold) and OSP (Organic Solderability Preservative) are used to protect the PCB and increase its longevity.

Testing and Quality Control

All high CTI PCB is tested strictly to ensure its performance and safety. This includes electrical testing, insulation resistance testing, and environmental stress testing. As a Top High CTI PCB manufacturer you can trust, we are keen on quality control to ensure delivery of flawless products.

1. Material Expertise: We are familiar with high CTI materials and have the capability to meet the most stringent insulation and safety requirements.

2. Custom Solutions: As leading High CTI PCB supplier, we can provide tailor-made designs for your unique application requirements. In high-voltage systems, industrial machinery, or automotive electronics products. Our processes utilize state-of-the-art technology to ensure accuracy, durability, and repeatability in every PCB.

3. Standard Compliant: Our manufacturing standards comply with international standards like IPC, UL and RoHS so as to make our High CTI PCBs your safest, most environmentally friendly and industry regulation compatible choice.

4. Competitive Price: However, our pricing is very reasonable for excellent quality, which makes us the most reliable High CTI PCB manufacturer for most customers globally.

High CTI PCBs are widely used, such as:

Applications requiring high voltage and which need To good insulation, to safety, and to reliability must use high CTI PCBs. Material procurement, quality control, testing, manufacturing, etc. are all essential to helping you get the best performance. Customized High CTI PCB Solutions as a leading High CTI PCB manufacturer, we promise to our customers best services and solutions. We believe that we can also meet your most demanding expectations for reliability and quality. Whether it is power electronics, automotive system, or industrial uses, you have any requirements of PCBs. Partner with us for your high CTI PCB requirements and see the difference in quality, performance and service.