-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

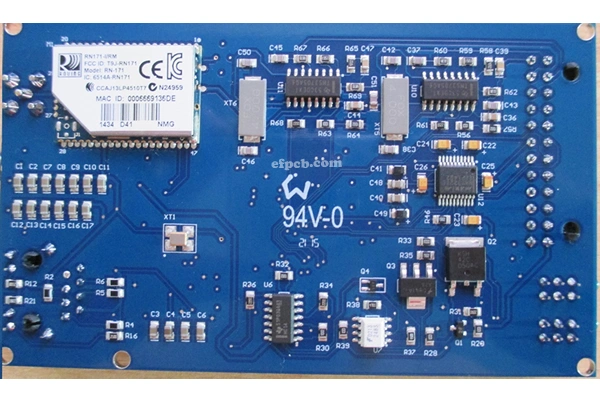

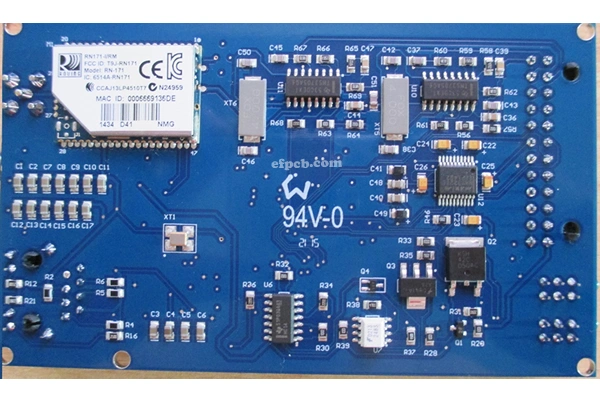

Part No.: E0615060189A

Layer count: 6 layer

Material: FR4, 1.6mm, 1 OZ for all layer

Minimum trace: 5 mil

Minimum space(gap): 5 mil

Minimum hole: 0.20mm

Surface finished: ENIG

Panel size: 168*108mm/1up

Application: Energy equipment.

Characteristics : multilayer, min packing 0201, Lead free assembly, ROHS compliant

Energy equipment is the foundation of modern infrastructure, serving industry, residential, and renewable energy applications. These systems rely on PCBA (Printed Circuit Board Assembly) boards that house complex electronic components to achieve dependable and efficient system performance. Choosing the PCBA board supplier for energy equipment is an important decision that can affect the performance, endurance and security of your product. In this article, we will walk you through what to look for when selecting a supplier, while demonstrating how our company can offer best-in-class solutions specifically designed for energy applications.

Electronic Printed Circuit Board (PCBA) based systems are energy intensive and need to be efficient at performing well. Solar inverters, wind turbines, industrial power controllers and energy storage systems – PCBA boards have been developed to meet the requirements of these high power loads, extreme environmental conditions and long operational life.

The global energy equipment market is set to witness significant growth, owing to the increasing penetration of renewable energy technologies and smart grid systems: Report by MarketsandMarkets. This expansion demonstrates the significance of working with an experienced PCBA board manufacturer that can fulfill the production requirements of energy applications.

Knowledge of Energy Equipment Applications

Energy system is produced in tough environment, which high voltage, temperature changing and EMI have impact on PCBA board. A competent PCBA board manufacturer should be well versed in energy based assemblies. We provide PCBA solutions for energy apparatus that are subject to rigorous operating environments.

Robust Tooling and High Volume Production

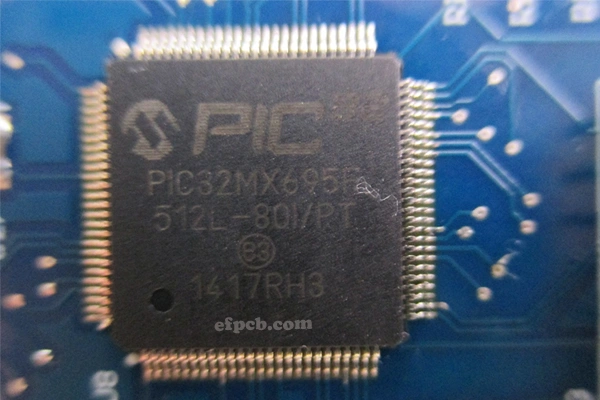

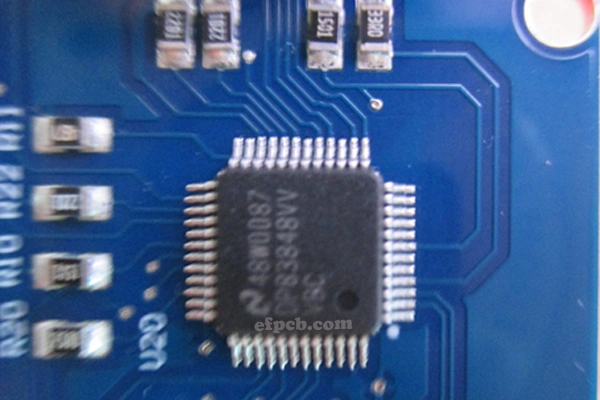

Technical PCBA manufacturing processes to cover the complexity of energy equipment, PCBA manufacturing must leverage processes such as surface mount technology (SMT), through-hole assembly, and hybrid design. Find a PCBA board manufacturer that can meet these standards and boasts modern production lines and advanced capabilities. We employ advanced technologies including automated pick and place machines, reflow soldering and inline inspection systems to achieve quality, efficiency, and reliability.

Quality Control and Certification

Durability is essential in power equipment, and herein lies the problem with solid electrolytes which are still largely untested — let a tiny part fail and your entire power grid, car city will go dark. The trusted PCBA board provider will have to meet high-quality standards of ISO 9001, IPC-A-610 and UL certificates as well. We are dedicated to quality and do strict testing in each process. These include automated optical inspection (AOI), X-ray inspection, and functional testing among others to guarantee each PCBA board is up to the highest performance and safety level.

Material Choosing and Durability

Energy equipment is subject to harsh conditions and therefore requires PCBA boards that are fabricated from resilient materials that can stand up to the harsh environment. A good PCBA board provider should have various selection of quality materials, example high temperature laminates, corrosion resistant laminate. We collaborate closely with customers to choose the appropriate materials for their energy-related applications, providing enduring performance and reliability.

Customization and Design Support

Energy devices typically need specialized PCBA boards to satisfy stringent design and application needs. A good PCBA board manufacturer should provide design support, prototyping and customization services. Our company provides full design support to maximize the performance, manufacturability and cost effectiveness of your PCBA board. Scalability and Lead Times

With the energy industry on the rise, producers require a PCBA board provider that can expand production effectively under the same lens of quality. Our efficient production and solid supply chain allow us to offer sustainable solutions with reasonable lead time, energy equipment projects on schedule.

Cost-Effectiveness

Top quality and reliability is what you want but do you want to pay for it? A reliable PCBA board provider should be priced reasonably while not sacrificing performance or longevity. Using bulk manufacturing and efficient production, we design and build your solution as per the requirements of your business and within the constraints of your budget.

Why Choose High Quality PCB as Your PCBA Board Supplier for Energy Equipment

We are a proven and reliable partner for energy PCBA board assembly providing expertise, accuracy and a customer focused solution to affordability and quality. Here are just a few reasons why we’re the best choice for energy equipment:

Specialized Expertise: We have been in the energy industry for many years, so we know what makes energy equipment unique and can provide customized PCBA board solutions to suit your needs.

Advanced Technology: Our ultra-modern plant and sophisticated technology make High quality, reliable and efficient products for you, each assembly. Quality at every step: From production to quality assurance, we meet the highest standards and take the necessary measures to ensure that each PCBA board can withstand the severe energy materials production environment.

Design and Assembly: We offer full design and assembly services to assist you in designing PCBA boards for maximum performance, cost, and ease of manufacturing.

Worldwide Delivery: With a good global network, logistics and marketing, we are able to provide good service to customers from all over the world.

In Conclusion: Selecting the best PCBA board provider for energy equipment will make all the difference in whether your product is a success or a dud. Applying the above considerations during the energy PCBA suppliers review can help you filter out a supplier that can deliver on your project needs and business goals.

We strive to be the best PCBA board provider for energy equipment to drive new ideas and possibilities in the energy industry. With technology, experience, and quality commitment, we are your best choice for PCBA board assembly. We can guide you as you energize the future with dependable and clean energy solutions.