-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

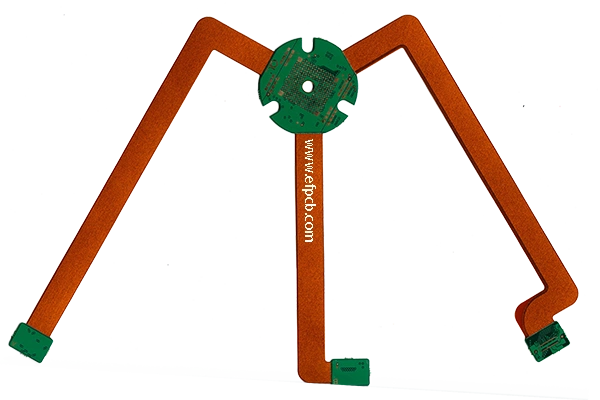

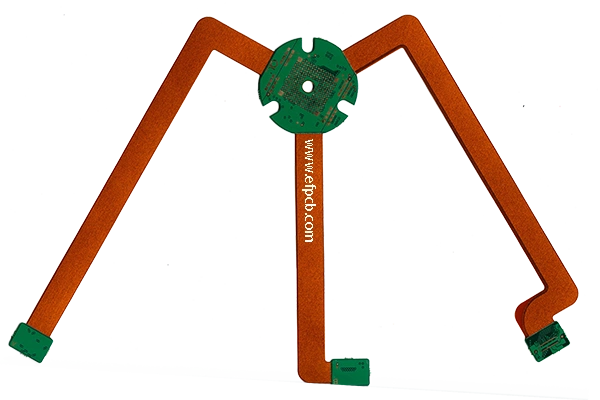

Part No.: E0618060279A

Layer count: 6 layer

Material: FR4 TG170, 1.6mm, high TG +2 mil PI, 1 OZ for all layer

Minimum track: 5 mil

Minimum space: 5 mil

Minimum hole: 0.20mm

Surface finished: ENIG

Panel size: 228*208mm/1up

Quick turn rigid flex pcb production has been on the rise in the current electronics world where everything needs to be delivered faster with more features. Rigid flex PCB, which is a combination of rigid PCB and flexible PCB, has been widely used in various fields involving compact size, high performance and reliability of electronic products, so rigid flex PCB is the necessary choice for modern devices. This article explores in detail each critical step throughout the quick turn rigid flex PCB fabrication process to secure robust performance and timely delivery.

Rigid flex PCBs are a type of PCB assembly which integrates rigid and flexible circuit substrates within a multilayer structure. This unique material combination allows the realization of 3D shapes, eliminates connectors and cables and improves signal integrity. Quick turn rigid flex PCB manufacture is all about shortening this timeline while maintaining quality, serving industries such as medical, aerospace, and consumer electronics where time-to-market is paramount.

The fabrication process starts with careful material selection. Good quality polyimide films are selected for flexible layers and FR-4 or equivalent materials for the rigid parts. Copper foils are bonded to these substrates to provide the basis for circuit patterns. When it comes to quick turn rigid flex pcb production, vendors need to keep a strong inventory to avoid wait and the materials must meet rigorous standards of performance.

Step processing after prematerial. A photoresist is placed on the surface of the copper clad substrate and the circuit pattern is exposed with UV light. The areas of copper exposed are then etched away leaving the traces behind with precision. So this process goes for each layer, whether it be rigid or flex. Because quick turn rigid flex PCB fabrication is speed intensive, high laser direct imaging is frequently implemented to reduce set time and improve precision.

Lamination is a significant step in which the rigid flexible layers are laminated. The flexible circuits are placed between two rigid layers through heat and adhesive creating a solid unit. This requires precision alignment to keep the flexible areas accessible and working. Automated lamination presses and accuracy registration systems are used to expedite production and reduce errors in quick turn rigid flex pcb manufacturing.

After lamination, the board is drilled for the vias and through-holes to provide electrical connection between layers. Laser and mechanical drills are employed for this purpose, depending on the size and location of the hole. These holes are then plated with copper to make them conductive. Quick turn rigid flex PCB fabrication requires precision drilling and automated plating lines to ensure fast delivery.

A solder mask is applied for protection of the circuit traces then surface finishes including ENIG, OSP are applied to improve solderability and life span. The finished boards are subject to comprehensive electrical and functional testing to confirm their performance and reliability. Every stage of the quick turn rigid flex PCB process is tailored towards generating a quality product on a tight schedule.

The final inspection includes visual and automated inspection to find any defects and inconsistences. After approval, the boards will be well packed and shipped to customer. Quick turn rigid flex PCB fabrication depends on precision process control and well trained staff to ensure every order meets specification and deadline, as well as on-time delivery. To conclude, quick turn rigid flex PCB fabrication is high-tech multistage process that brings together novel materials and engineering methods with advanced fabrication process. By mastering each stage of the process, manufacturers can create high performing, reliable PCBs that fuel the next generation of electronic innovation.