-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

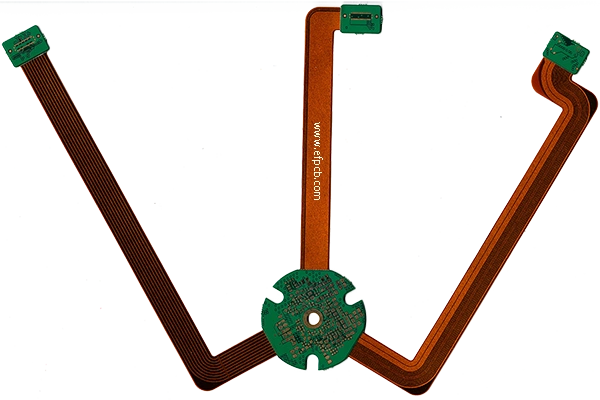

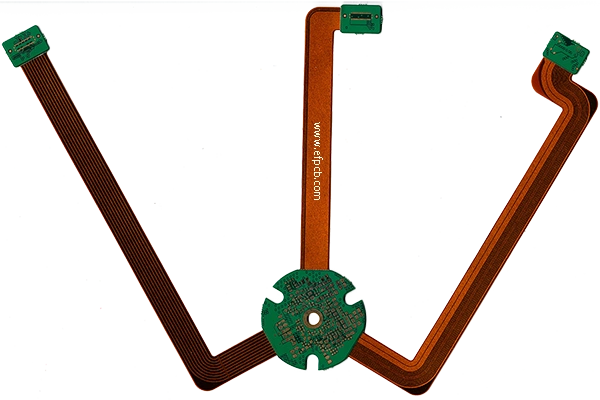

Part No.: E0415060279A

Layer count: 6 layer

Material: FR4 TG170, 1.6mm, high TG +2 mil PI, 1 OZ for all layer

Minimum track: 5 mil

Minimum space: 5 mil

Minimum hole: 0.20mm

Surface finished: ENIG

Panel size: 228*208mm/1up

In the high-speed world of electronics, the capacity to manufacture intricate circuit boards quickly with impeccable quality is a must-have. Rigid flex PCB manufacturer services make it possible to obtain hybrid PCBs that have the durability of rigid boards and the adaptability of flexible circuits. These boards are commonly found in aerospace, medical instruments, and high-end consumer electronics where reliability and small form factors are important. This article not only describes how to maintain speed but also precision in the production process that quick turn rigid flex PCB manufacturer follows.

Material Preparation and Choice

The scheme for a quick turn rigid flex PCB manufacturer: The procedure for a quick turn rigid flex PCB manufacturer begins with a selection of materials. Rigid Circuits – Usually the rigid parts are FR-4 or other high grade laminates, Flex Circuits – the flexible parts are constructed from polyimide films due to superior mechanical and thermal performance. All the substances are very well cleaned and conditioned to eliminate impurities or substances that might damage the attachment or the electrical functionality. Then, the stack-up design is engineered to include multi layers of rigid and flexible material that are alternated to provide the specific circuit performance. This phase is vital in confirming the structural and operational quality of the end product.

Circuit Imaging and Etching

After the stack-up has been formed, the quick turn rigid flex PCB manufacturer moves on to circuit imaging. Photolithography is a process that printing accurate circuit designs on both rigid as well as on flexible substrates. A photosensitive resist is coated on the surface, exposed to ultraviolet light through a mask and developed to expose the copper traces. The unnecessary copper is then etched away chemically, allowing for the production of intricate circuitry required by high-end application. During this process, precision is key, as even minor misregistration or imperfection can lead to failure of the board.

Drilling, Via Formation, and Plating for Rigid Flex PCB

Then holes are drilled for vias which electrically connect the different layers of the PCB, too . Laser drilling is typically used to form microvia in flexible sections, mechanical drilling is usually adopted for large hole in rigid portions. The quick turn rigid flex PCB manufacturer also plates these vias with copper to make a solid signal transmission. Good via formation is important to ensure that no such issues occur as voids or misregistration which could compromise the circuit’s reliability and durability.

Coverlay Application and Routing

Flexible sections of the PCB are covered by a coverlay, usually a polyimide film, to protect the circuitry from mechanical strain, moisture and foreign material. The coverlay is applied with heat and pressure by the quick turn rigid flex PCB manufacturer keeping the flex in its flexibility state Flattened. Additional rigidity is added by having a solder mask applied onto the rigid sections. Final the board outline is routed, this cuts the PCB stack to size ready for the assembly.

Surface Finishing and Quality Control

Surface finishing, for example: ENIG (Electroless Nickel Immersion Gold) or OSP (Organic Solderability Preservative), will be applied on exposed copper pads for better solderability and prevent oxidation of the copper. The quick turn rigid flex PCB manufacturer also performs multiple inspections such as Automated Optical Inspection and Electrical Testing to verify pattern integrity, layer registration, and quality. Only those boards that pass the test are sent out for assembly or use.

Our quick turn rigid flex PCB manufacturing procedures mix sophisticated material science, accurate engineering and stringent quality control to bring you dependable, high-performance PCBs on aggressive delivery schedules. To make quick turn rigid flex PCB manufactures conquest for development and the innovation in every industry where rapidity and trust are the maxim.