-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

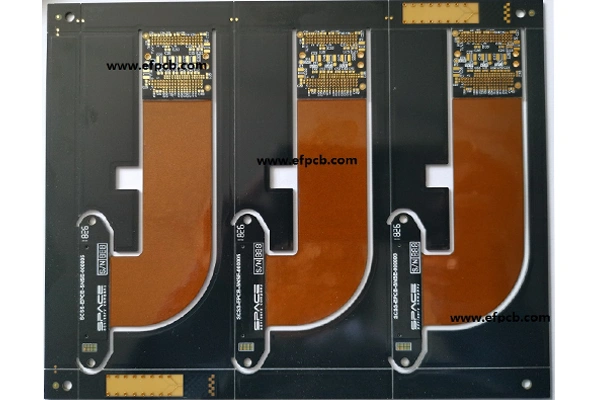

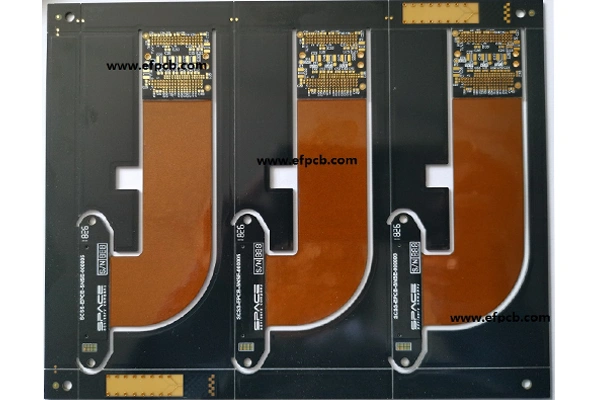

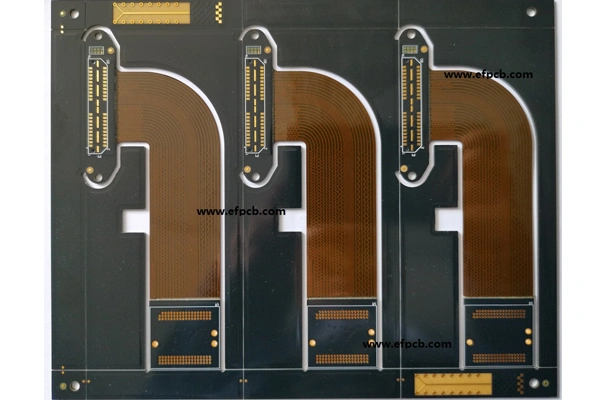

Layer count: 8 layer

Material: FR4, 1.6mm, TG 180 + 2 mil PI, 1 OZ for all layer

Minimum track: 4 mil

Minimum space: 5 mil

Minimum hole: 0.25mm

Surface finished: ENIG

Panel size: 228*158mm/3up

Rigid flex PCBs (Prints Circuit Boards) are gaining more and more traction in industries such as aerospace, medical devices and consumer electronics because they allow the strength of rigid boards with flexible circuits to be combined. These mixed boards bring a new option for small size, lightweight, or high-density complicated design. However, Rigid flex PCB manufacturing process is complex, complicated and should be done with great care and detail. In this article, you'll learn the ins and outs of how to manufacture a rigid flex PCB, and the things that need to be taken into the account when you work with a manufacturer.

Rigid flex PCBs are composed of rigid and flexible layers, forming an entire multilayer unit. Bending and folding is made possible by the flexible layers while structure is provided by the rigid panels. This pairing makes them a great choice for size-constrained applications in which system reliability is paramount.

The production of rigid flex PCBs is a complex and demanding process which demands specialized equipment and very precise engineering and quality control. They make the necessary industry grades and must be quality checked such as required at the end of the day.

Material Selection

The rigid flex PCB production process is available at Rigid Flex PCB., What is the process in rigid flex should be followed material that means the first step in producing a rigid flex pcb is that deciding the right materials. Manufacturers will use polyimide for the flexible layers with excellent thermal and mechanical properties. For the rigid parts, ordinary FR4 is used.

To make the conductive layers, copper foils are laminated on these substrates. The copper and substrate material thickness should be properly selected, considering the application and size of the board.

Designing the PCB Layout

Summary the design stage is vital to the success of rigid flex PCB. Using sophisticated CAD (Computer-Aided Design) tools along with other software utilities, engineers are able to design flexible sections that can endure multiple bends continually without jeopardizing the integrity of the circuit.

Some important features:

Define Bends: Flexible PCB sections are designed with minimum bend radii to avoid cracking or delamination.

Stack-up Considerations: The mix of rigid and flex layers needs to be tailored to achieve the right balance of performance and manufacturability.

Signal integrity: Trace routing is important to reduce signal loss and interference. Drilling and Hole Formation

Then is drilling where holes for vias, through-holes and mounting holes are drilled. Producers employ high precision drilling machines in with the accuracy. Laser drilling is a common choice when forming microvias, especially so with complex, high-density designs.

Lamination

Lamination is an important process in the rigid flex circuit. This technique lines the rigid and flexible substrates while applying heat and pressure. The lamination process parameters must be tightly controlled to prevent the air bubble, misalignment, and peeling off.

In some instances, sequential lamination is required whereby several lamination steps are involved. It paves the way for more complex designs and more layers.

Imaging and Etching

After lamination, photoresist surfaces of copper layers are imaged to comply with the circuit patterns. The uncovered copper is chemically etched away, removing unwanted traces and pads.

Manufacturers need to have exact alignment in this stage to prevent the production of defects, such as short circuit, or open circuit.

Plating and Surface Finish

The process continues with plating a thin layer of metal (usually copper) onto the exposed surfaces, including the walls of the drilled holes. This guarantees the electrical connection between the layers. After plating a surface finish is applied to prevent the copper traces from oxidizing and enhance solderability. Popular finishes are ENIG (Electroless Nickel Immersion Gold), HASL (Hot Air Solder Leveling) and OSP (Organic Solderability Preservative).

Solder Mask and Silkscreen

To prevent solder bridging in assembly and to establish some protection for the traces, a solder mask is salted onto the PCB. The silkscreen layer is subsequently added to print labels, component markings and other identifiers.

Testing and Quality Control

The rigid flex PCB is subjected to exhaustive testing before it is sent to the buyer to make certain that it fulfills all of the criteria. Typical testing include:

More advanced techniques like automated optical inspection (AOI) and X-ray inspection are frequently employed by manufacturers to detect defects that cannot be seen with the bare eye.

Finishing Assembly

After the rigid flex PCB has been approved at all levels for production, it is ready to be assembled. The components are mounted on the board by a process known as surface-mount technology (SMT) or through-hole soldering. The manufacturers should be verified board structural to confirm, flush, press and stack up the layers with correct handling and assembling process.

Nevertheless, rigid flex PCBs pose some difficulties for the producers:

Design Complexity: The combination of rigid and flexible layers must be accurately engineered and designed with sophisticated tools.

Rigid flex PCBs have revolutionized the electronics industry, providing design freedom and performance reliability that can be considered groundbreaking. Still their production process is sophisticated and requires specialized knowledge at each step. From raw material selection and design to lamination and testing, the manufacturers must adhere to stringent protocols if they want to produce the best product.

By working with a professional rigid flex PCB manufacturer, companies can take full advantage of these advanced boards to develop cutting-edge products that fulfill the requirements of today's technology. If your design is for aerospace, medical or consumer electronics rigid flex PCBs are likely to be part of the answer for a tough and versatile application.