-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

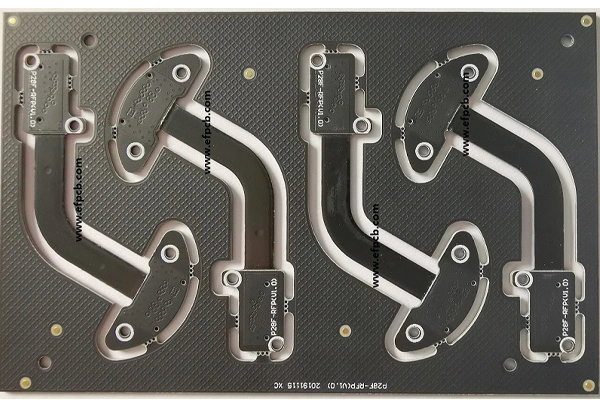

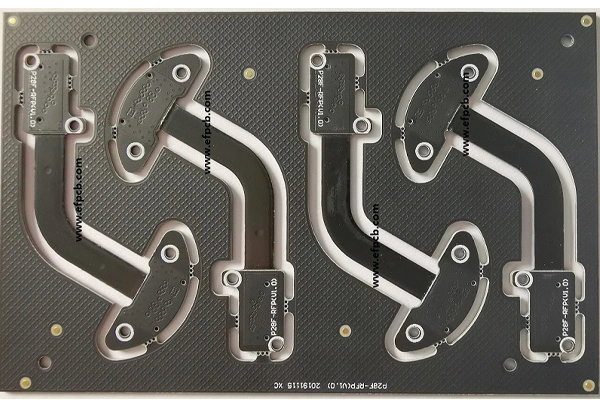

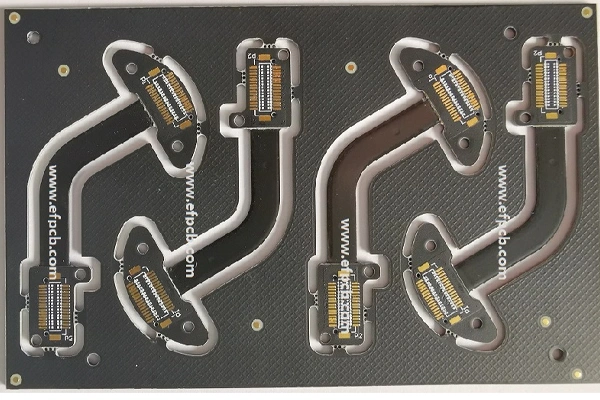

Part No.: E0415060179A

Layer count: 4 layer

Material: FR4, 1.6mm, high TG +1mil PI, 1 OZ for all layer

Minimum track: 5 mil

Minimum space: 5 mil

Minimum hole: 0.25mm

Surface finished: ENIG

Panel size: 98*228mm/4up

Medical device rigid flex PCB production is a specialized process that demands precision, high technology, and the observance of quality standards. These PCBs are crucial components in medical devices where the need for reliability, durability, and performance is high. Compliant with IPC Class 3, these rigid flex PCBs provide long-lasting operation in a-aggregate medical devices. We cover everything from medical device rigid flex PCB design through the production process with end to end responsibility. This article describes the production procedure and shows some of the special characteristics of our products.

Medical device rigid flex PCBs are multi-layer circuit boards that consist of rigid and flex panels which allow for both strength and flexibility. This special construction makes them suitable for small and complicated medical devices such as pacemakers, hearing aids, diagnostic instrumentation and surgical tools. IPC Class 3 qualification means that PCB will perform reliably and at high quality in even the most demanding applications where you simply can’t afford to fail. With our rich experiences as a medical device rigid flex PCB manufacturer, we are able to produce high quality PCBs that comply with the most stringent industrial standard. Our products are designed with the end user in mind and able to withstand the harshest conditions in the medical industry while providing the highest levels of reliability, signal integrity and long life.

It is important to understand that the manufacturing of this product involves the following steps or pans, all of them equally critical. Summary of the manufacturing of medical device rigid flex PCB The manufacturing of rigid flex is much tighter controlled and closer watched. So it is very important to realize every step perfectly to meet the IPC Class 3 and the special medical application requirements.

Material Preparation and Selection

The high-quality materials which are made of are compliant with RoHS and have IPC class 2 and class 3 standard. Generally rigid layers are made of FR4 layers and flexible layers are made of polyimide due to its superior thermal stability, flexibility as well as good mechanical. These must be biocompatible materials that can withstand sterilization processes and the rigors of use in a medical environment.

As the excellent medical device rigid flex PCB producer, we only adopt top materials which comply with the most stringent medical and industry standards. Our section of PCB manufacturing is the backbone of our business and responsible for 12% of global PCB production.

Circuit Patterning of Rigid Flex PCB

Circuit patterning entails making electrical connections on the PCB. High precision circuit patterns are formed by advanced photolithography and etching processes to conform to the high density interconnection of medical applications. Patterning process must keep tight tolerances to ensure uniform performance for IPC Class 3.

We employ advanced laser direct imaging (LDI) and fine-line etching technology that provides the highest level of accuracy. We guarantee that the rigid flex PCBs for medical devices can satisfy the with the complex design requirements of sophisticated medical devices.

Drilling and Via Formation

Drilling is the process of forming vias, or small holes, that stack up the layers of the PCB. These vias are plated with copper to have reliable electrical conductivity. For medical device applications, vias need to be capable of withstanding rigorous IPC Class 3 requirements to be considered reliable.

As a leading and proven medical device rigid flex PCB manufacturer, we leverage advanced via technologies, such as microvias and blind vias to help you achieve higher interconnect density that delivers superior electrical performance. Experience lean manufacturing precision drilling process.

Layer Lamination and Bonding

The rigid and flexible layers are laminated together under a specific pressure and temperature to form a multilayer PCB." This process creates a good bonding force between each layer and the PCB mechanical stability is also improved. For medical device uses, the lamination process must incorporate a combination of flexibility, and strength.

Our lamination processes...are developed to allow high levels of uniformity and precision making warpage resistance and long term reliability possible. This helps us maintain the highest quality level, which enables our products to meet the demanding requirements of IPC Class 3 and be used in the med environment.

Rigid Flex PCB Surface Finish and Solder Mask Application

Surface finish is added to protect the copper traces and enhance the solderability. Typical finishes are ENIG and OSP. Apply a solder mask, the solder mask insulates the PCB and prevents short circuits during the assembly process.

We provide superior surface finishing solutions to meet your application needs for medical device rigid flex PCBs. Our finish provide excellent solderability and superb corrosion and long-term reliability that are extremely important in medical related PCBs.

Tests and Quality Control

The last stage in medical device rigid flex PCB fabrication is precision quality control and testing. This includes electrical test, bare board AOI and reliability testing to verify that the PCB meets all IPC Class 3 requirements. As a medical device rigid flex PCB manufacturer you can trust, we utilize high-end inspection equipment including automated optical inspection (AOI) and x-ray scanning to identify defects and protect consistent quality. Each and every PCB is thoroughly tested to ensure the best quality for life critical applications.

We have specifically engineered our medical device rigid flex PCBs to handle the medical industry's unique demands. Here are some of the core competencies which makes us unique:

IPC Class 3 Quality: our rigid and flex PCBs can be used in life critical medical devices as they meet the highest reliability standards.

Compact and Lightweight Design: Our PCBs can be customized to be ultra-compact and lightweight medical instrumentation and devices.

Excellent Flexibility & Strength: With the combination of rigid and flexible layers, our Rigid-Flex PCBs can also achieve high mechanical strength and flexibility.

Superior signal integrity: We design with leading-edge materials and techniques to reduce the attenuation of signals and the generation of noise, so signal integrity is preserved, and we have accurate and dependable data.

Sterilizable and Biocompatible: Our PCBs are constructed to tolerate sterilization and request for biocompatibility, making it an ideal product for medical applications.

Custom Solutions: We collaborate with our clients to create custom solutions on PCBs based on their specific requirements and performance needs.

Sustainable Production: Sustainability is a fundamental value of our company. We utilize green manufacturing processes and materials where possible to minimize environmental waste.

Manufacturing medical device rigid flex PCBs: The manufacturing process of medical device rigid flex PCBs is intricate and involves a lot of complexity and has to be done using latest IPC Class 3 technology. Excellent Medical Device Rigid Flex PCB Manufacturer Agency with Innovative Design, Advanced Technique and High Quality Production Capacity We are committed to the best quality and highest reliability medical device rigid flex PCB and excellent service.

Our medical device rigid flex PCBs are built to meet life-critical application needs, with the durability, flexibility and electrical performance required by next generation medical devices. When customers choose to work with us, they can rest assured they will be provided with well-made PCBs that will allow them to innovate and keep their medical technologies safe and effective.