-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

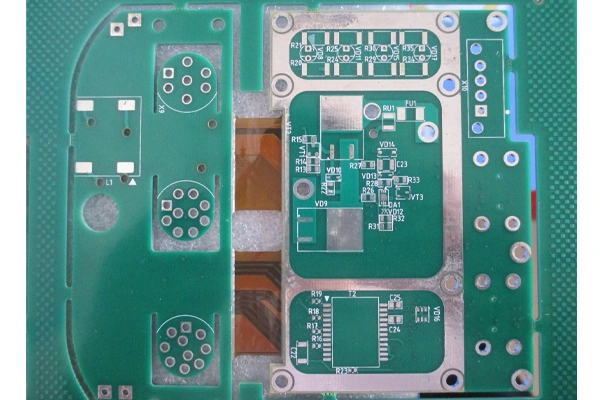

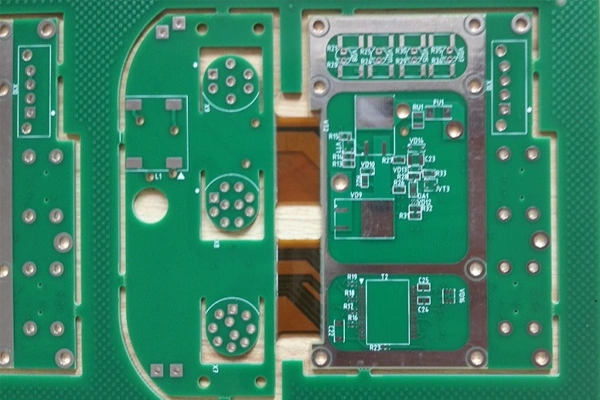

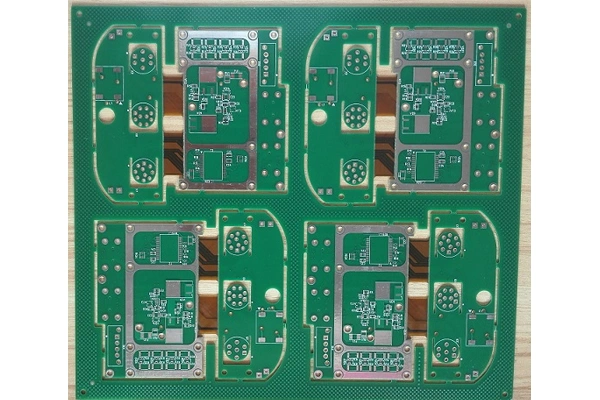

Part No.: E0815060179A

Layer count: 8 layer

Material: FR4, 1.6mm, high TG +3 mil PI, 1 OZ for all layer

Minimum track: 5 mil

Minimum space: 5 mil

Minimum hole: 0.25mm

Surface finished: ENIG

Panel size: 228*258mm/4up

IPC Class III rigid flex PCB production is a quality precious process and need high end equipment and processing, engineering and quality assurance. They are commonly found in space and aviation, medical, defence, and high-reliability communications where performance and ruggedness are imperative. Being a reliable rigid flex PCB manufacturer, we are dedicated to providing you with high quality products that comply with the IPC Class III. In this paper, the main processes of IPC class III rigid flex PCB manufacturing are introduced, the characteristics of the products of our company is expounded.

IPC Class III is the most rigorous standard of printed circuit board, developed by IPC. PCBs that satisfy IPC Class III requirements are intended for use in high-reliability applications where failure is not an option. Rigid flex PCBs have the sturdiness of rigid boards and the flexibility of flexible circuits, are best suited for these kinds of applications. With our manufacturing expertise in rigid flex PCB, we are able to provide solutions that meet the IPC Class III requirements for PCBs that need to offer high reliability, high performance, and stiffness in extreme environment.

The processes of manufacture for rigid flex PCB is similar to those of rigid board and flexible circuit board. The process of manufacturing IPC class III rigid flex PCB is a multi-stage process. Each stage is essential to make sure that the end product is with highest quality and high performance. Material Selection and Materials Preparation

The work begins with a good decision on the quality of material to use and the proper preparation of that material. The manufacturing begins with the finest quality materials that conform to the high standards of the IPC class III. These are rigid, e.g. FR4, and flexible, e.g. polyimide, materials. The materials are required to have outstanding thermal, mechanical and electrical properties to meet the application under the severe environment.

As a top rigid flex PCB supplier, we use best quality raw materials that guarantee high performance and durability. We are guided in our selection of materials by the unique demands of the IPC Class III specification - we want every PCB in your product to be the best it can possibly be.

Circuit Patterning

Circuit patterning is an important process of forming pathways for electricity in the PCB. This consists of spinning on a photoresist layer, exposing it with light through a mask and then chemically or plasma etching away unwanted copper to leave behind accurate circuit patterns. The traces on IPC Class III rigid flex PCBs must have a consistent tight tolerance for electrical performance.

We leverage state-of-the-art laser imaging and fine-line etching techniques to handle the design complexity of circuit patterns with high precision. It allows our rigid flex PCBs to satisfy the demand of IPC class III and we can make sure an excellent performance in high strain environments.

Drilling and Via Formation

Drilling is the process of forming vias, small holes that make an electrical connection between the different layers of the PCB. Vias are then plated with copper, to ensure good conductivity. For IPC Class III rigid flex PCBs, the vias must be capable of meeting the quality standards required to ensure reliability and electrical integrity.

Rigid flex PCB Fabrication and Drilling: Our expertise as a rigid flex PCB fabricator allows us to offer advanced via solutions including microvias and blind vias. We have the proven processes to meet your rigid-flex high quality requirements.

Layer Lamination and Bonding

The rigid and flex layers were laminated together under pressure to form the multilayer construction of the rigid flex PCB. As a result, the bonding between layers has a strong adhesion force, and the mechanical strength of the PCB is promoted. Our lamination process is controlled for consistency and accuracy so that the PCBs have little or no warpage and the structural strength is good. This level of care means that our products are made to the highest standards of IPC Class III.

Surface finishing and solder mask application

Surface finishing is to protect the copper trace with a layer of protection and to enhance the ability of soldering. Typical finishes are electroless nickel immersion gold (ENIG) and organic solderability preservatives (OSP). A solder mask is then placed over it to cover the PCB and to keep from short circuit in the assembly.

With our wide selection of surface finishes, you can customize your rigid flex PCB for IPC class iii reliability. Our state-of-the-art finishing systems provide outstanding solderability, corrosion protection and heat resistance.

Testing and quality assurance

The Process of Production IPC Class III Rigid Flex PCB Quality Control & Testing is the last stage in production of IPC Class III rigid flex PCB. Which include electrical test, dimensional check and reliability test to verify that the PCB conforms all specifications.

As a professional rigid flex PCB manufacturer, we have advanced testing equipment, such as automated optical inspection (AOI), X-ray imaging, etc., to identify defects and guarantee uniform quality. Our commitment to quality ensures that every PCB production fulfills or surpasses the IPC Class III standards.

We manufacture our IPC Class III rigid flex PCBs to provide excellent performance and dependability in such environments. There are also some key features that make the products stand out:

It is a very involved process to produce clean and well manufactured IPC Class III rigid flex PCBs, from the design to the manufacturing challenging technology, precision engineering with patience and diligence is required. At our rigid flex PCB manufacturing facility, the synergy between innovation, expertise, and cutting-edge technology enables us to bring you products that are reliable and high performing. Our IPC Class III rigid flex printed circuit boards are built to meet the requirements of high-end critical applications, delivering the strength, flexibility, and electrical performance that high-end aerospace, medical, and military applications demand. When customers work with us, they have the confidence to say yes to the most challenging projects, because we provide them with industry-leading rigid flex PCBs that make innovation possible and success sustainable.