What is Flex PCB Manufacturing Process?

Flex circuits have emerged as the quiet powerhouse behind sleek devices, denser packaging, and products that can withstand motion, heat, and continuous flexing. The right choice of partner is important as the performance of flex is influenced as much by process discipline as by design. This intro discusses "what to look for" in a contemporary flex PCB manufacturer, concentrated on those product features which translates into real-world reliability.

What Flex PCBs Are Enabling in Modern Products

Flex isn't just about “making it bend.” It is about transporting electronics in dynamic spaces and being stable electrically and mechanically. A good flex PCB manufacturer enables applications such as wearables, medical sensors, cameras, automotive modules and industrial equipment where rigid boards are challenged. Core value propositions include:

• Removable interconnects in place of bulky wire harnesses

• Greater assembly efficiency through the reduction of connectors and solder joints

• Enhanced signal integrity with controlled stack up and shorter routes

• Greater resistance to vibration or repeated motion stress.

Flex PCB Production capabilities which determine performance

Flex circuits are constructed from materials such as polyimide, with adhesives and copper systems chosen to suit the electrical and bend needs. Process control is what separates a circuit that is good for years from one that isn't good for a few thousand cycles. A true flex PCB manufacturer will have invested in stable lamination, tight imaging registration, and clean drilling and plating to ensure that delicate features can hold over multiples. Search for products and solutions with the following capabilities, or solutions that combine these capabilities and more for prototyping and volume production:

• Single-sided, double-sided, multilayer flex constructions

• Rigid-flex constructions that incorporate rigid areas for component placing

• Fine line and spacing for dense layouts and high pin-count components

• Laser drilling for microvias and enhanced interlayer connectivity

• Controlled impedance options for high-speed designs

Flex PCB Product Features that Count on the Assembly Line

Product “features” should minimize the risk of assembly and simplify integration. The best programs are designed to be producible, not just printable. A good flex PCB manufacturer will customize stack up, coverlay openings, and stiffener placement so you aren't fighting the board in SMT and final assembly. Features choices typically are:

• Coverlay for protection against abrasion and for insulation in bend areas

• Selective stiffeners in FR4, polyimide, or stainless steel for ZIF connectors and component areas

• Surface finishes like ENIG, immersion silver, or OSP tailored for your soldering profile

• Reinforced pads and strain relief to augment pull-out strength

Quality, Reliability, and Traceability

Flex reliability is hardly discernible with the naked eye, so qualification testing and traceability are crucial. A good flex PCB Manufacturer performs inspections and testing throughout the manufacturing process, not just at the end. Electrical testing on all panels, plus dimensions checks and micro section analysis on critical programs. Reliability-enhancing tests/panels include:

• Copper thickness and plating uniformity control

• Adhesion and peel strength tests of flex layers

• Bend and thermal cycling testing if required by the application

• Lot traceability linked to material lot, process parameter, and inspection results.

Flex PCB Engineering Support and Fast, Predictable Delivery

Flex work goes speedier when the vendor can interpret design intent into a manufacturable process design. High Quality PCB as an established flex PCB manufacturer offers DFM advice early, suggesting modifications that will lower cost or enhance yield without sacrificing performance. This includes advice on bend radius, copper balancing, tear stops, coverlay clearances, stack up symmetry. But operational strength counts, too — Quick-turn prototypes with a clear path to scale process documentation aligned with customer standards Consistent lead times and packaging that prevents handling damage

A Practical Takeaway for Selecting the Right Partner

Flex circuits reward careful collaboration. The best flex PCB manufacturer has expertise in materials, precision process control, and production discipline, and provides transparent quality data. Combined, these factors deliver flex circuits that assemble cleanly, withstand real world stress, and have proven electrical performance from prototype to volume production. Selecting a reliable flex PCB manufacturer is a decision that will have positive implications on your product performance, customer acceptance, and overall cost of ownership in the long run.

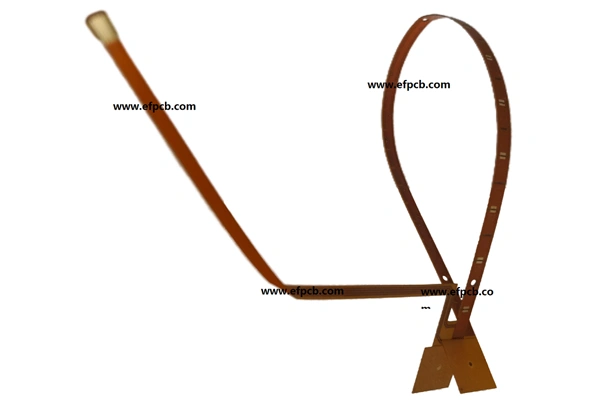

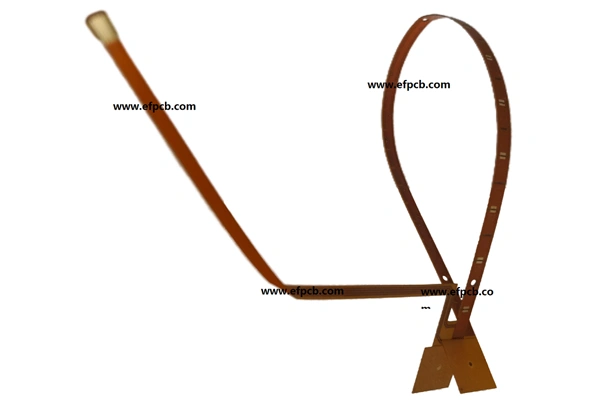

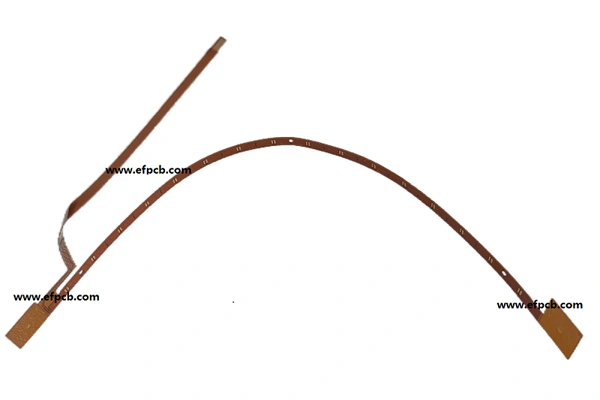

Medical Devices Flex PCB Application