-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

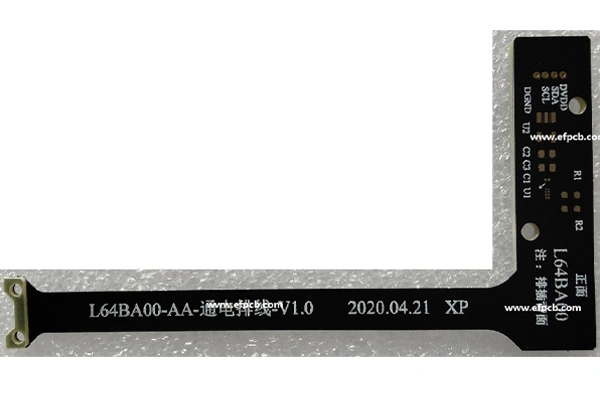

Part No. : E0215060369C

Layer count: 2 layer flex PCB

Material: Polymide and FR5, 0.15mm,0.5 OZ for all layer

Minimum trace: 7 mil

Minimum space: 6 mil

Minimum hole: 0.20mm

Surface finished: immersion gold

Panel size: 238*68mm/1up

Flexible Printed Circuit Board (Rigid-flex PCB) has changed the electronics world as it allows solutions that were not possible with ever more complex rigid designs. High Quality PCB as one of the top quality flex PCB manufacturer, our expertise is to provide premium, dependable and high customized solutions for modern technology needs. In this article, we will give a comprehensive guide to flex PCB fabrication with the characteristics and capabilities that make us unique.

Flex PCBs are used in products that need to bend, twist or flex or where it is needed to save space. Flex PCBs have unique benefits in a wide range of industries, such as medical technology, automotive and industrial equipment, wearable technology and more. A reliable flex PCB manufacturer makes sure that these benefits come alive with high precision engineering and manufacturing.

The following are some of advantages of Flex PCBs:

Our manufacturing process is validated to the most exacting quality and performance standards. As a flex PCB manufacturer, we are equipped with the most advanced machines and advanced technologies to make the best Flex PCBs which meet your expectations. Our services are:

Designed to bring out elite level of performance under the toughest conditions, our Flex PCBs will certainly live up the environment in which they are deployed. We collaborate with our clients and work on products that are manufacturable and reliable. Salient Features of our Flex PCBs:

Everything we do as a flex PCB manufacturer is based on quality.” We apply stringent quality control standards at all levels of the production process, ensuring that every Flex PCB shall meet or exceed industry standards. We go through quality control such as the follows:

We know that a successful Flex PCB project is about more than having manufacturing capability. As a flex PCB manufacturer, we offer full technical support on engineering to assist in achieving your design objectives. Our team provides

Selecting the best flex PCB manufacturer is critical for you projects success. With strong manufacturing capability, good quality assurance, thoughtful services, and all-round support from the robust technical team. High Quality PCB is high level and stable, and the whole company has a strong ability to innovate. Whether you're creating advanced new wearables, medical devices, or automotive systems, we're here to help you bring your air vision: PCB recipe OEM solutions: RF product solutions:

Partner with us and discover the difference that a reliable flex PCB manufacturer can make to your product success. With cutting-edge products and superior support, we can assist you in every stage from design to manufacture to optimize your PCB solutions. Robust flex circuits: extreme core options, excellent conductor coverage, and thin flex structures combined with permitting large hardship to your flex circuit, excellent flex performance and durability. We specialize in high quality rigid and flex PCB solutions. From simple to complex rigid, rigid-flex, and multi-layer flex PCB, our solutions are compatible with your needs and requirements. With our customer-oriented policy and flexible range of services, you can always rely on us to handle even the most challenging and complex projects smoothly.