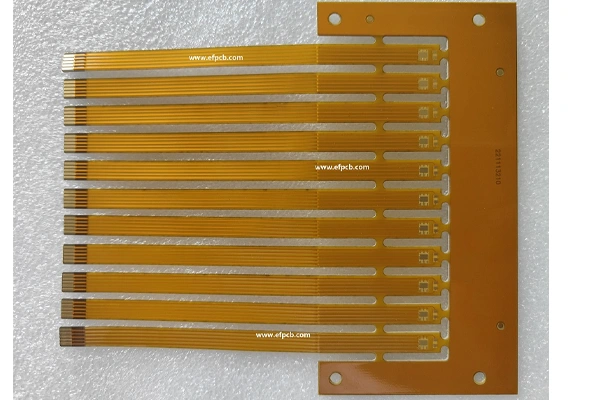

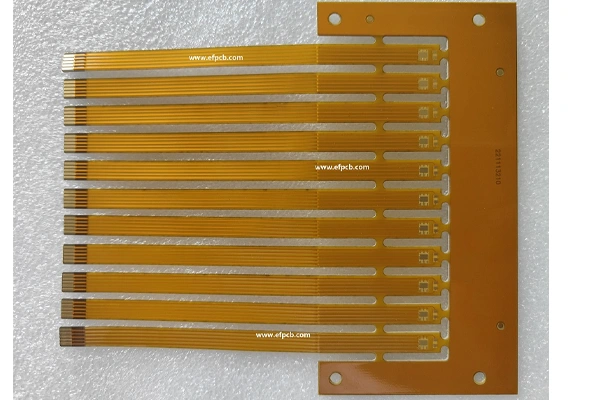

How to Produce Stiffener for Flexible Printed Circuit Board (FPCB)

FPCBs have been widely employed in modern electronics because of the features such as light weight, small size, flexible nature and so on. However, sometimes parts of an FPCB should be strengthened to hold connectors, components, or mechanical stress points. This is where the stiffener comes in. Knowing the process of stiffeners manufacturing is a must have knowledge to every FPCB maker who wants to provide FPC solutions in good, stable quality and delivery.

The Effect of Stiffeners on the FPCB Production

Stiffeners are an additional layers of materials, bonded to localized areas of an FPCB to increase mechanical strength and stability. They are not electrical conductive but hold together, so make easier assembling and connector mounting. An experienced FPCB manufacturer will always use stiffeners to protect critical areas from excessive bending or damage, ensuring the overall strength and reliability of the circuit.

Selection of stiffener material

The importance of stiffener material selection for the performance and compatibility. Popular stiffener materials are FR-4 (glass reinforced epoxy), polyimide, and stainless steel. Here are some of the unique benefits

• FR-4 is typically selected for/easy to reasons of its strength and low cost.

• Polyimide stiffeners are flexible, with a level of reinforcement.

• Stainless steel stiffeners are suitable stiffener strength is insufficient. The selection of materials with good performance for the application is very crucial for an experienced FPCB manufacturer.

Application process of stiffener

Application of stiffeners consists of skull popping precision steps. This is how a typical professional FPCB manufacturer produces stiffener:

Design and Preparation

During the FPCB design, the engineers can specify the shape, size, and location of the stiffener. The stiffener must perfectly correspond to the shape of the reinforced area and should not disrupt the function of the circuit.

Cutting and Shaping

The stiffening materials are cut with laser cut, routing or die punching. Precise cutting results in snug fit and dependable performance.

Surface Cleaning

The surface of both FPCB and stiffener is cleaned to eliminate contaminant. This is an important step for good bonding between layers.

Adhesive Application

An appropriate adhesive — generally a heat-activated or pressure-sensitive variety — is applied to the stiffener or the surface of the FPCB. Depending On the Assembly Process and the Material choice is.

Laminating and Bonding

The stiffener is set down onto the region of the FPCB. By applying heat and pressure, the adhesive is activated, which fastens the stiffener to the board. Top FPCB fabricators closely monitor temperature & pressure to prevent warping or misregistration.

Inspection and Quality Control

After bonding, the assembly is examined for alignment, bond strength, and surface completeness. A trusted FPCB manufacturer will carry out comprehensive quality testing to confirm that the role of the stiffener is upheld for the life of the product. An FPCB manufacturer, by taking such steps, can manufacture flex circuits with strong, accurately positioned stiffeners to provide the best in terms of performance and reliability even in high end applications.