How to Manufacture Microwave PCB?

A microwave PCBs is a customized PCB which is designed to work at high frequency normally ranging from MHz to GHz. These PCBs are vital for applications including radar, satellite communications, wireless networks, and aerospace technology. As a professional manufacturer of Microwave PCB and RF PCB, we are committed to providing our customers with the best quality and high performance solutions that could satisfy the unique requirements of these high-end products.

What Are Microwave PCBs?

To perform at such high frequencies, microwave PCBs use materials with outstanding electrical characteristics, including a low value of dielectric constant (Dk), and low value of dissipation factor (Df). These features guarantee minimal signal loss and assured performance even at high frequency. Note that, unlike regular PCBs, microwave PCBs require specialized materials such as PTFE (Teflon), Rogers laminates, ceramic-based or metal-based substrates. As a leading microwave PCB manufacturer, we are fully aware of these issues and have brought up revolutionized approach to comply with top industry requirements.

Key Steps in Manufacturing Microwave PCBs

Microwave production is precision-engineered, using advanced materials, and tight quality control. Listed below are essential stages in the manufacturing process:

Material Selection

Substrate material is the basis of any microwave PCB. High Dk and Df materials will cause distortion of the signal, but too low of a Dk will also lead to performance problems. Typical material includes Rogers, Taconic, and other PTFE like laminate. A premier microwave PCB supplier, we assist customers in material selection based on their unique application needs.

Microwave PCB design is more challenging than standard PCB design because high frequency signal are very sensitive. Designers need to control impedance, reduce crosstalk, and route signals efficiently. Our skilled professionals use sophisticated simulation techniques to design layouts that will provide the best performance.

Copper Cladding and Etching

After the substrate material is chosen, the copper layers are laminated to the surface. The copper is etched to form specific patterns of circuits. For microwave PCBs, tight tolerances must be held through the etching process to guarantee accurate impedance control.

Plating and Surface Finishing

Special finishes are typically required on ceramic PCBs to meet performance, reliability or other special requirements. Typical finishes are ENIG (Electroless Nickel Immersion Gold) or Ag plating, which are excellent for conductivity, as a barrier to oxidation. As a professional microwave PCB manufacturer, we adopts advanced plating technology to get stable results.

Multilayer Lamination

Microwave PCBs can be multilayer too, for the more complex circuits. The laminating process is to be carried out closely so that all layers will be mated and bonded well. Special tools and techniques are employed, to minimize bow or twist.

Drilling and Formation Of Via

Drilling and via formation are quite important processes in establishing connections between layers. Drilling of microwave PCBs must be precise otherwise it can harm the substrate and the signal path.

Testing and Quality Control

Each microwave PCB is tested rigorously to ensure it performs to spec. Tests are impedance control, signal loss testing and thermal reliability testing. As a trusted microwave PCB manufacturer, we focus on quality control to provide you with non-defective products.

Why Choose High Quality PCB In Manufacturing Your Microwave PCB?

1. Advanced Materials Expertise

We've got years of experience in dealing with high frequency materials such as rogers, Taconic, ptfe laminates. We can help you choose the right material.

2. Custom Solutions As a reputable microwave PCB supplier, we provide custom designed solutions to meet your unique requirements. Be it single layer or double layer or multilayer PCBs, we can serve you with the best solutions.

3. Precision and Accuracy

Our state of the art manufacturing processes and engineering are able to hold tight tolerances, impedance control, and low loss, which allow our microwave PCBs to be used for very high frequencies applications.

4. State-of-the-Art Equipment

We invest in the new technology and new equipment to guarantee the best quality. Utilizing state of the art drilling technology to advanced testing equipment to automated function testing systems, we have the capabilities to provide dependable and effective solutions.

5. Quality Commitment

We are ISO, IPC and RoHS compliant microwave PCB manufacturer with years of experience. This confirms our products are safe, they are good for the environment and the results comply with the top industry standards.

Applications of Microwave PCBs

Microwave PCBs are essential for a wide range of applications and industries, such as:

- Telecommunications: 5G networks, antennas, base stations.

- Aerospace: Radar systems, satellite communication, navigation devices.

- Medical Devices: Enabling imaging at high frequencies, diagnosis tools.

- Automotive Electronics: Advanced driver-assistance systems (ADAS), vehicle radar.

Conclusion

The production of microwave PCB is not as easy as ordinary PCB, it needs experienced hands to handle with accuracy and needs special equipment to manufacture because it must suit high frequency use. Each phase of the process plays a vital role in maintaining the performance, from material selection and designing to testing and quality assurance. High Quality PCB as a professional microwave PCB manufacturer, we offer tailor-made high quality solutions to satisfy specific requirements of our customers. Whether you are in need of a simple design or a complex multilayer PCB, we can produce dependable products that meet your expectations. Mate with us and your requirements of Microwave PCB and feel the difference in Quality, Performance and Service.

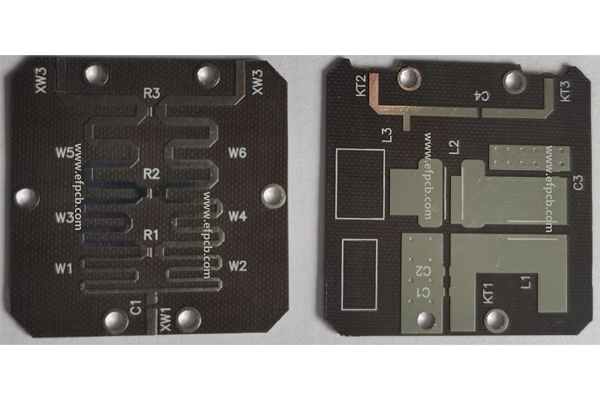

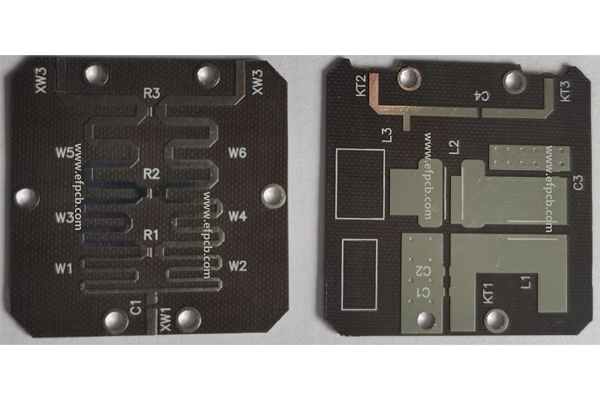

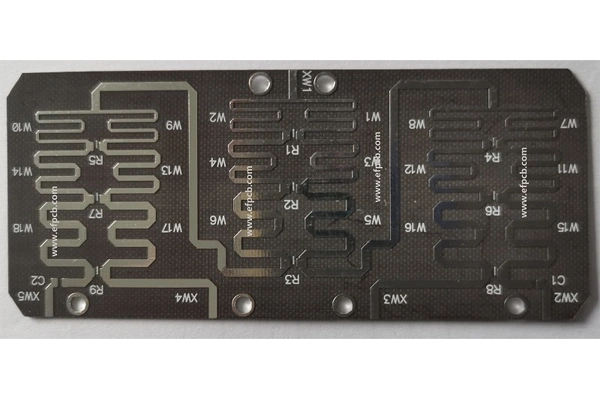

Telecommunication equipment, antenna mainboard application