-

Mail Us Todaysales@efpcb.com

-

Company LocationShenzhen, Guangdong, China

-

+86-755-23724206Call us for more details

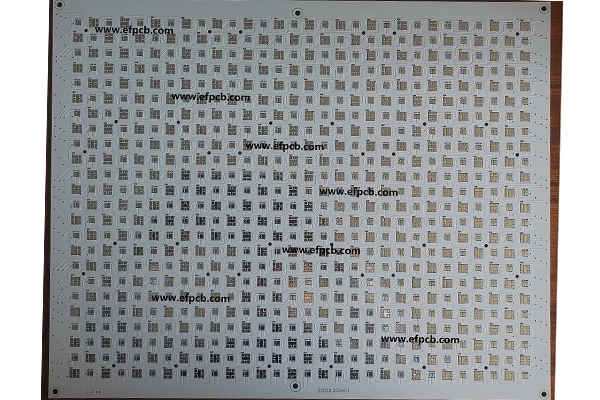

Part No.: M0295362169A

Layer count : Double Sided Aluminum Core PCB

Material: Copper core, 1.6 mm, 1 OZ, 5 W/M*K

Minimum track: 20 mil

Minimum space: 20 mil

Minimum hole: 0.5mm

Surface finished: Lead free HASL

Panel size: 288*268mm/1up

Double sided metal core PCB manufacturing process is a unique process, which determines the reliability and efficiency of the electronic equipment. The excellent heat dissipation and thermal conductivity characteristics make these PCBs extensively applied in the automotive, LED lighting, telecommunication and power electronic industries. As a reputable double sided metal core PCB supplier, we are committed to providing high quality products for the special requirements of these applications. This blog covers the manufacturing process and key features that differentiate our product.

Double sided metal core PCBs have a metal layer, such as aluminum, steel or copper, at their core that is placed between layers of dielectric material. Heat dissipation unlike conventional PCBs, these boards can dissipate heat well from high power devices, so they have reliable performance and long service life. With conductive layers on each side, double sided metal core PCBs enhance the design possibilities, enabling more intricate circuits and a higher number of components. With our MC PCB experience, we know the necessity of accuracy and innovation to develop products with high-level for electronics today. Our process is focused on providing PCBs that exhibit high thermal dissipation, high mechanical stability, and high electrical reliability.

There are several precise processes involved in the manufacturing of double sided metal core PCBs. All procedures are necessary to guarantee the final product quality, performance, and using life.

Metal Core PCB Material Selection and Preparation

The procedure starts with choosing the right metal core material — usually aluminum or copper, based on the application. These are the metals with the best thermal conductivity and mechanical properties. A dielectric layer is also fabricated to electrically separate the metal core and the conductive layers.

Our company, the top double sided metal core PCB manufacturer in the industry, have some of the best temperature controlled materials available in the market and at the same time able to electrically insulate. We process these materials with the precise attention to detail that our customers’ applications demand.

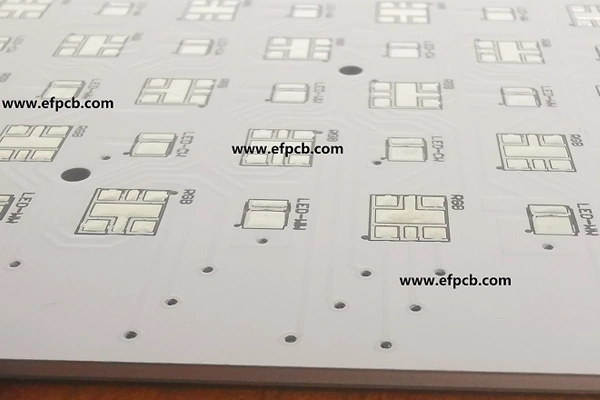

Circuit Patterning

Circuit patterning is the process of writing the copper traces (paths that are electrical conductors) on both sides of the PCB. This is done through sophisticated photolithography and etching processes. The dual inline design permits more elaborate circuitry and a greater number of elements.

Utilizing state-of-the-art laser imaging and high precision etching processes, we produce tightly packed circuit patterns with very small tolerances. This is because we have used the double sided design enables you to design with an infinite amount of layers heat-sink metals core PCBs.

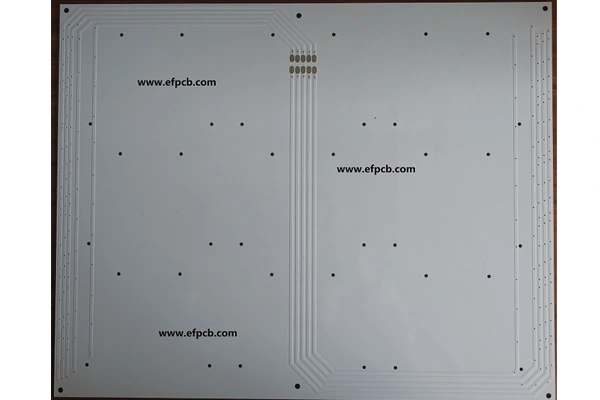

Drilling and Via Formation

Drilling is an important process to create connections between two layers or conductors. Vias (small holes) are drilled through the PCB so that electrical signals can flow between the upper and lower layers. These vias are also plated with copper for better conductivity.

As leading double sided metal core PCB manufacturer, we also offer state of the art via solutions such as microvias and plated through-holes. We ensure precise drilling with our CNC drilling services that guarantee optimal electrical connectivity and proper alignment.

Lamination and Layer Bonding

The metal core, dielectric, and the conductive layers are laminated under a specific pressure and temperature. This creates a solid bond between the layers and strengthens the mechanical stability of the PCB.

Our lamination process is fine-tuned to create consistency and accuracy, so your lamination assisted PCBs will be flat, robust and resilient. This pride in our work is what enables us to stand behind the strength and quality of our products.

Surface Finishing of Metal Core PCB

Finishing surface is used to cover the copper traces and enhance solderability. Typical finishes are electroless nickel immersion gold (ENIG) and organic solderability preservatives (OSP). These finishes improve the oxidation and corrosion resistances of the PCB.

We provide several types of surface finishes to meet customer requirements. Owing to our modern finishing facility we are able to produce excellent solderability and long term reliability which makes our double sided metal core PCBs suitable for the most challenging applications.

Quality Control & Testing

Now, it's time to subject for the quality assurance tests. This includes electrical, thermal, and dimensional testing to verify that the PCB meets your specifications.

Our sophisticated testing machinery enable us to test performance and reliability of every PCB. As a double sided metal core PCB manufacturer dedicated to quality, we guarantee that every product is in line with industry standards.

Our ground breaking double sided metal core PCBs are built to achieve high performance and reliability for challenging environments. Below are some of the features of our products:

Producing double sided metal core PCBs is a multi-step procedure that involves the use of sophisticated machinery and highly skilled personnel. As a leading manufacturer of double sided metal core PCBs, we combine the knowledge and skills of the electronics industry to create solutions for the electronic technology of the future.

We have designed our PCBs to survive the specific demands of such industries as automotive, LED lighting and telecommunications. Customers can now purchase high quality double sided metal core PCBs with excellent performance, reliability and cost-effectiveness by working with us.